A GUF for all purposes

An overview of the diversity

of mk’s belt conveyor variants.

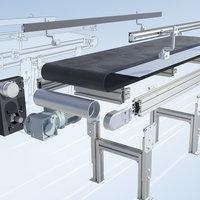

With the rise of industrial automation, belt conveyors have taken on most of the transport tasks involved in production processes. Nowadays, wherever you look, you’ll find belt conveyors in all different designs and versions.

Belt conveyors are suitable for almost any industrial application in which piece goods are to be transported without any particular requirements in terms of their orientation or positioning. All different shapes and dimensions, packaged or unpackaged, light or heavy, can be transported using a belt conveyor.

For these applications, mk offers an enormous range of standardised, modular belt conveyor systems, also called GUF. The design options are virtually unlimited: any width from 50 mm to 2 m, any length from 300 mm to 20 m, loads of up to 350 kg, and speeds of up to 80 m/min.

Thanks to a compact design using aluminium profiles, the conveyors are easy to integrate into existing production lines, even complex ones, and to adapt as necessary. The profile system makes the design highly flexible, and lateral profile grooves provide ample options for mounting attachments and accessories.

In addition to straight segments, belt conveyors are available in double-line, inclined and curved versions. Special designs are available for clamping, scanning, vacuum and magnetic applications as well as in stainless steel for the food and pharmaceutical industries.

The right system for any application

mk developed a standard straight belt conveyor in the mid-1970s. Today, innumerable further developments later, it forms the heart of the portfolio of mk conveyor technology. Over the years, versatile belt conveyor series of all different sizes and weight classes have been created. The perfect conveyor can be configured for virtually any type of goods, transport or environmental conditions.

Small Conveyor GUF-P Mini – The smallest series, GUF-P Mini, is particularly well-suited to transporting and separating small components with low volumes and weights. It is available in widths of 75 to 150 mm and in lengths of 360 to 5,000 mm. Thanks to its minimal installation height, this conveyor is ideal for use in complex systems where space is at a premium. Since the belt recirculation is integrated in the conveyor frame, the conveyor can be placed directly on the machine bed.

Versatile Belt Conveyor GUF-P 2000 – The GUF-P 2000 series is the all-rounder for light- to medium-weight goods based on the mk 2000 profile. It is extremely versatile thanks to the large assortment of available drives, tails, stands and belt types. This series is characterised by a low height of 50 mm and a compact ø 53 mm driving roll as well as a wide variety of different belt types. Furthermore, the system is available with an optional stationary or rolling knife edge. Due to the maturity and standardisation of this series product, its delivery times are particularly short.

Sturdy Belt Conveyor GUF-P 2041 – Based on the mk 2251 profile, the sturdy GUF-P 2041 series was developed for high belt loads of up to 150 kg and for conveying goods up to 1200 mm wide. It uses an 85-mm driving roll that affords highly efficient transmission of the motor’s power. The series is available with a virtually unlimited selection of different belt types, including designs with cleats and side walls, and numerous combinations of drives, tails and stands, with knife edges and drum motors as options.

Heavy Belt Conveyor GUF-P 2004 – The GUF-P 2004 is the largest series, based on the mk 2004 profile, and features a 105-mm roller. Capable of handling a total load weighing up to 200 kg and measuring up to 2,000 mm wide and 20,000 mm long, this torsion-resistant conveyor frame provides easy transport of particularly heavy loads and bulky goods. It can be complemented with reinforced accessory components such as side rails and stands.

Double Belt Conveyor DGF-P 2001 – The dual-line DGF-P 2001 series is particularly well-suited for transporting pallets. Its very small idler rollers allow it to transport even short pallets, for example those used in assembly systems in the electronics industry. The belt runs entirely atop wear strips, which allows for a maximum weight of 15 kg per section.

Cleanroom Belt Conveyor GUF-R 2000 – The GUF-R 2000 belt conveyor is certified for demanding use under cleanroom conditions. Based on the GUF-P 2000 conveyor system, it has been optimised to ensure the lowest possible levels of particle emissions. Furthermore, the conveyor uses a surface-cooled smooth-surface motor that produces very little air turbulence during operation. Thanks to its smooth and large surfaces, the conveyor is particularly easy to clean. The system version with the AF drive has been certified by the Fraunhofer Institute IPA with an air cleanliness class of 4 in accordance with DIN ISO 14644-01 standards.

Left, right, up and down

Other designs such as curves and inclines make it possible to construct three-dimensional conveying paths. These modules are entirely compatible with each other to allow uninterrupted conveying. Predetermined space requirements can be used or adapted for, bridged or detoured around, using any combination of straight, curved and inclined conveyors.

Curved Belt Conveyor KGF-P 2040 – The KGF-P 2040 series of curved belt conveyors conveys goods around a curve of either 90 or 180 degrees. This series is available in usable widths of 300 to 600 mm and is equipped with a rolling knife edge with a diameter of 20 mm to ensure transferral of small conveyed goods. Belt tensioning is handled by an automatic tensioning device, which is integrated in the tail, keeping the conveyor’s outer dimensions constant.

Incline Conveyor KFG-P 2000 – The KFG-P 2000 series of inclined belts is based on the well-proven mk 2000 profile and allows vertical transport and connecting different levels of belts. The incline angle is variable, and various belts, cleats, stands, funnels, slides and side rails can be selected. Equipped with rollers for mobility, this series is particularly well-suited for mobile use in filling containers or lattice boxes. The KFG-P 2000 ECO is a design of the KFG-P 2000 series restricted to 18 different versions. ECO stands for economical, meaning an optimised cost/benefit ratio, which is reflected in the conveyor’s affordable price and quick delivery times.

Tailored to customer requirements

A comprehensive portfolio of accessories allows further options for completing a conveyor system. In addition to a large selection of stands, side rails and drives, mk offers belts in a variety of materials to suit the task and the goods to be conveyed.

Drives – The standard mk range for configuring a new conveyor system offers a variety of in-stock motors from well-known manufacturers. Depending on the choice of motor, the load to be applied to the belt and the type of operation, conveyors can achieve speeds of up to 80 m/min. Power transmission can occur directly via the drive shaft or indirectly using a chain, no matter whether the belt is operated continuously, in reverse or in cycles. This additional option to adjust the transmission ratio allows you to achieve very fine speed increments. Positioning can be accomplished with a head drive at the infeed or discharge end, with a lower belt drive for reversing operation, or with an internal drive (drum motor) without obstructing edges and low particle emissions.

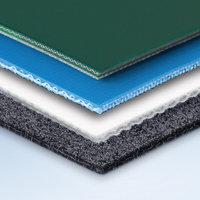

Conveyor belts – In order to best handle any type of goods under diverse conditions, mk provides a wide selection of standard belt types. Materials and textures are available for nearly any conveying application, including accumulating belts with low friction for continuous accumulated operation and laterally stiff belts to allow pushing products off the side of the belt. In addition, belts can be antistatic, FDA-compliant, oil-compatible and cut-resistant.

Cleats and corrugations – For transporting bulk dry goods, or to overcome inclines, the belts can be customised with weld-on profiles. These profiles can be lateral or longitudinal cleats or side walls that are additionally welded onto the belt conveyor. Lateral cleats function as cams on inclined conveyors, while side walls serve to keep the conveyed goods in place. They can be used instead of side rails and are often employed in incline conveyors. Longitudinal cleats serve primarily as belt guides.

Transitions – At transitions between one system and another, e.g. from a curve to a straight segment, the transfer of small products can be accomplished using a “knife edge”. This may be an idler pulley with a particularly small diameter (a rolling knife edge) or a fixed edge over which the conveyor belt slides (stationary knife edge).

Stands – The conveyors can be equipped with stands in various types, designs and weight classes to suit the environmental and application conditions. These include compact single stands with foot plates, sturdy height-adjustable H-profile stands with levelling feet, and fixed or swivel casters for mobile use. The stability of the conveyor system depends on the ratio of its height to its width, the load’s centre of gravity and environmental factors. Using the mk aluminium profile system affords almost limitless possibilities for building the structure.

Side rails – There are various types of side rails available for positioning the conveyed goods on the conveyor and for infeeding and discharging the products. These include simple sheets, stainless steel bars and aluminium profiles with wear strips, which may be rigidly connected to the conveyor or adjustably screwed into the slot in the side of the conveyor frame profile. Adjustable side rails are customisable in the usable width and the height of the rails.

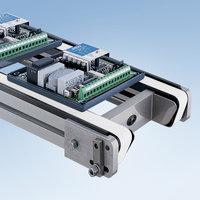

Additional equipment components – The mk portfolio contains many additional attachments and services to serve a wide variety of requirements and functions, including initiators for controlling, positioning and monitoring processes, end stops for process-dependent accumulation of conveyed goods, drip pans for catching pollutants, and full-featured control systems for process integration.

Easy online configuration of belt conveyors

mk offers the QuickDesigner configuration tool to help you configure a custom belt conveyor easily and conveniently. This tool helps with configuring any customised belt conveyor of the GUF-P Mini, GUF-P 2000 or GUF-P 2041 series, with no installation of software required.

Your on-screen entries are checked for plausibility immediately, to ensure that you are always offered the ideal conveyor. Each input field has an info button that provides detailed notes in order to make the tool as easy as possible for you to use.

Once your conveyor is fully configured, the tool automatically generates a CAD model immediately. If desired, it can also generate a quotation. The created configurations, with the associated models and quotations, can be accessed and even edited further at any time via the “My Account” menu.

Just the tip of the iceberg

The variety of the conveyor systems from mk is practically endless. Aside from the proven belt conveyors, the portfolio also includes chain, timing belt, modular belt, and flat top chain conveyors as well as roller conveyors. The extremely sturdy modular belt conveyors are more wear-resistant than belts and can be employed anywhere that goods with sharp edges are to be conveyed. The multi-strand chain conveyors are typically used for transporting pallets. And roller conveyors dominate logistics with boxes and pallets. Whether the goods to be conveyed are loose piece goods, boxes, crates, pallets or workpiece carriers, any transport task is manageable.

This product range is complemented with rotary tables for simple, economical buffering, storing and separating workpieces and with linear modules for precision linear handling.

The team from mk is ready to provide any assistance needed by mechanical engineers and designers who aren’t sure which conveyor system is best-suited to their intended application. Our conveyor technology experts have years of experience in finding solutions for applications of all different kinds.