Automatica 2018 – Conveyor Technology and Transfer Systems for Automation and Material Flow

At automatica 2018, the international trade fair for intelligent automation and robotics in Munich, conveyor technology specialist Maschinenbau Kitz will present its conveyor technology modules used for feeding and interlinking, as well as its innovative system solutions for transporting workpieces, from 19–22 June 2018. Both the modular Versamove transfer system and the SPU 2040 accumulating pallet recirculation system will be the focus of mk’s trade fair stand. In addition, mk will present a selection of belt conveyors and, for the first time, the efficient flat top chain conveyor systems of E-M-M-A, its new subsidiary.

Transporting workpiece carriers and workpieces is a necessary part of automated and networked parts production. The transport should therefore be flexible and precise, ideally offering integration of robots and RFID recognition. mk’s newest system solution modules, equipped with its modular construction kits for profile, conveyor and linear technology, meet these requirements and can be used in virtually all fields related to automation and material flow.

In addition, mk will display exhibits from its new subsidiary, E-M-M-A, for the first time. The E-M-M-A flat top chain conveyors, also known as plastic chain conveyors, fill a gap in mk’s portfolio and are used in all areas of industry, including the automotive industry and its suppliers, as well as the electronic, chemical, pharmaceutical, detergent, confectionery and cosmetic industries. Virtually any track design within a three dimensional space is feasible with the flat top chain conveyors. They can transport piece goods as well as workpiece carriers with loads of up to 20 kg per piece. Various chain widths and side rails make product widths between 10 and 400 mm possible. The E-M-M-A flat top chain conveyors have been used for many years with great success and can reliably transport various kinds of products to their destination.

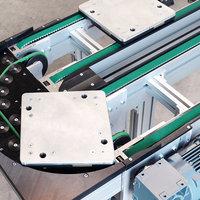

The modular Versamove transfer system, optimally tailored to customer requirements, will also be on display. Versamove is a solid and reliable high-quality system for transporting workpiece carriers. Divided into three weight and size classes (standard, plus and ultra), it always has the right system for any application. Versamove’s modular design allows for quick and transparent scheduling and project planning. While developing the system, we ensured its compatibility with systems that are currently available on the market. As a result, third-party workpiece carriers can be used on the Versamove standard. Whether it’s for individual modules or complete solutions, mk offers comprehensive service for the Versamove, including control, start-up and maintenance.

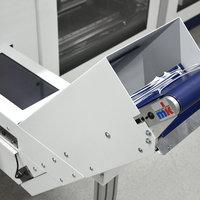

In addition, mk will present the accumulating pallet recirculation system SPU 2040, which is used for cost-effectively interlinking machining stations and reliably feeding, buffering, positioning and separating workpieces in tight spaces. The workpieces on the workpiece carriers/pallets are transported by the flat top chain conveyor to the upper transport level. After the workpieces are removed, the empty workpiece carriers are safely carried over the tail and then conveyed back suspended below the transport level. They are then available at the start of the belt to be loaded with new workpieces. Neither a second conveyor level nor lift-and-lower units are necessary. It also eliminates the need to load workpiece carriers on the belt, whether manually or automatically.

In addition to the transfer systems, mk will present a selection of belt conveyors from the conveyor technology division used for feeding and interlinking. These are extremely well suited for transporting piece goods without special requirements regarding their location and position. Thanks to the closed belt surface, it is possible to transport products with any kind of base geometry.

With years of experience in conveyor technology, the mk team is your first contact for application-specific and technical questions relating to factory automation.

automatica 2018, 19–22 June 2018, Munich, Hall A5, Stand 304