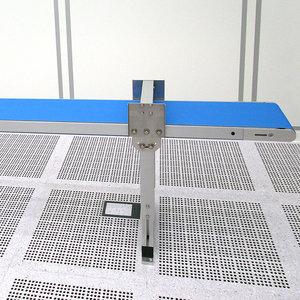

Certified belt conveyor system for cleanroom tasks

Task

A conveyor is required that operates with especially low emissions for the demanding use in cleanrooms. In addition, operation must not cause any air turbulence, or only very little, in order to prevent dispersion of tiny particles in the room. The conveyor must be suitable for cleaning in compliance with cleanroom conditions and must not have any hidden or open spaces where dust might collect.

mk solution

Based on the GUF-P 2000 conveyor system, the GUF-R 2000 cleanroom conveyor was developed with the lowest possible particle emissions. Thanks to the use of a surface-cooled smooth-surface motor, the conveyor produces hardly any air turbulence during operation. Thanks to its smooth and large surfaces, the conveyor is also particularly easy to clean. The system version with the AF drive has been certified by the Fraunhofer Institute IPA with an air cleanliness class of 4 in accordance with DIN ISO 14644-01 standards. Series 50 closed cleanroom profiles and stainless steel levelling feet were used to set up the conveyor.

- Certified air cleanliness class 4 in accordance with DIN ISO 14644 in no-load operation, and air cleanliness class 5 with 20 kg in accumulation mode

- The wear-resistant belt is especially designed for operation in cleanrooms and causes practically no micro-particles

- All components that come into contact with products and belts are made from stainless steel

- Special smooth-surface motor without impellers guides heat over smooth surfaces instead of cooling fins

- Encapsulated direct drive with no critical wear components such as drive chains

- Conveyor frames based on mk Series 50 cleanroom profiles with closed slots

- Flexible operation in reverse, accumulation and cyclic modes

Customer benefits

- Versatile thanks to modern design and anodised accessories

- Ideal for integration into existing cleanrooms

- Virtually emission-free > air cleanliness class 4

Used products