Problem definition

Design, construction and start-up of a semi-automated workstation interlink system for rotating assemblies for stretching synthetic fibres. The workpiece carriers are provided in three different variants for the rotors, the housings and the finished assemblies. Part of the…

High-Quality Transport Systems Starting at Batch Size 1

mk supports innovations in the machine and system construction sector, from the prototype all the way to standardised production. Our experts develop and produce custom-tailored solutions for all sorts of production and supply chain applications – wherever transfer technology needs to be perfectly integrated into your systems.

Problem definition

A feed unit is to be used to push wooden beams into a saw and automatically cut them to custom-made size. A linear module is used to generate variable cutting lengths based on predetermined values provided by the control system. The cycle time for sawing the length of one beam is…

Problem definition

The customer required a palletiser with a connected tray recirculation system: Pallet trucks are used to feed Euro pallets loaded with trays into the system and then remove them again at the end of the process. The palletiser destacks filled trays from the pallets and feeds them…

Problem definition

Heavy loads should be transported via a conveyor system. The transport system should have a transfer that is as free of gaps as possible. The transport mass can briefly weigh as much as a ton and the linear speed should be between 0.03 - 0.3 m/min (high-speed values and…

Problem definition

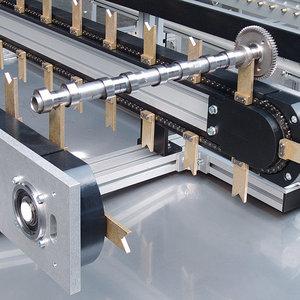

Camshafts are conveyed into a processing machine (lathe), separated and positioned, so that the camshafts are clamped into the processing machine identically every time. Since the aim is to process different types of camshafts, the width of the conveyor system must be variably…

Problem definition

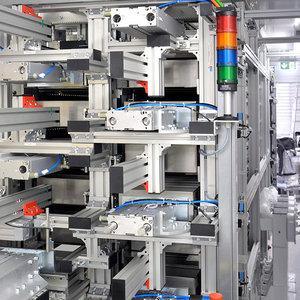

In order to link a manufacturing process, during which a machine that is integrated downstream, functions at a slower speed but operates longer, a transfer system is required using a buffer zone for 40 pallets arranged in 5 levels and capable of transporting a total load of 10…

Problem definition

For use with our patented, automation-ready reusable trays known as IKLTs (innovative small load trays), the customer requires a low-cost automation solution with semi-automatic transfer and an automatic unit for stacking and unstacking the trays from the base of the transport…

Problem definition

Empty or loaded trays for turned steel parts are to be loaded or unloaded in a fully automated process. For the subsequent automation, the trays are to be buffered upstream and downstream of the palletizing station. Thus, after manual loading of the empty-tray buffer, the system…

Problem definition

To feed and discharge containers from a multi-level storage system, the containers need to be raised to the various storage levels and then lowered again by a parallel storage line. The available space is very limited. The machine should be as reliable and require as little…

Problem definition

Flexible lightweight frame for a salt-water treatment system that is characterized by a long service life. The system is completely assembled in Germany and subsequently dismantled, in order to then be ultimately commissioned at the implementation site. Consequently fast…