Belt recirculation integrated into the conveyor

frame to permit placement directly on the

machine bed

Very small tail diameters keep gaps at

product transfer points narrow

Wide variety of drive units and belt designs

to suit any application

Profile design provides a torsion-resistant

structure and good load-bearing properties

Flexible operation in reverse, accumulated

and cycling mode

23

2

The low installation height and the lower

side walls for placing the conveyor directly

onto the machine bed are ideal for the

direct discharge of light and small products

(from an injection moulding machine, for

instance). The small tail diameters prevent

large gaps during product transfer. The

profile design ensures a torsion-resistant

structure with good load-bearing properties.

The values for the total load, speeds,

and so on, specified below are directly

related to this design and may vary as a

result.

The driving rolls of the various drive versions

can be rubberised to suit the application,

so that motor torque can be optimally

transmitted. Crowned driving and

idler rollers simplify belt adjustment and

help the belt to run in the centre of the

conveyor frame. A stainless steel sheet is

mounted under the running surface of the

belt to ensure sustained wear resistance.

The conveyor frame keys ensure that the

belt returns within the conveyor frame.

Benefits of the GUF-P MINI

Transport and separate small products with

low volume and weight

Very low installation height for easy integration

into complex systems

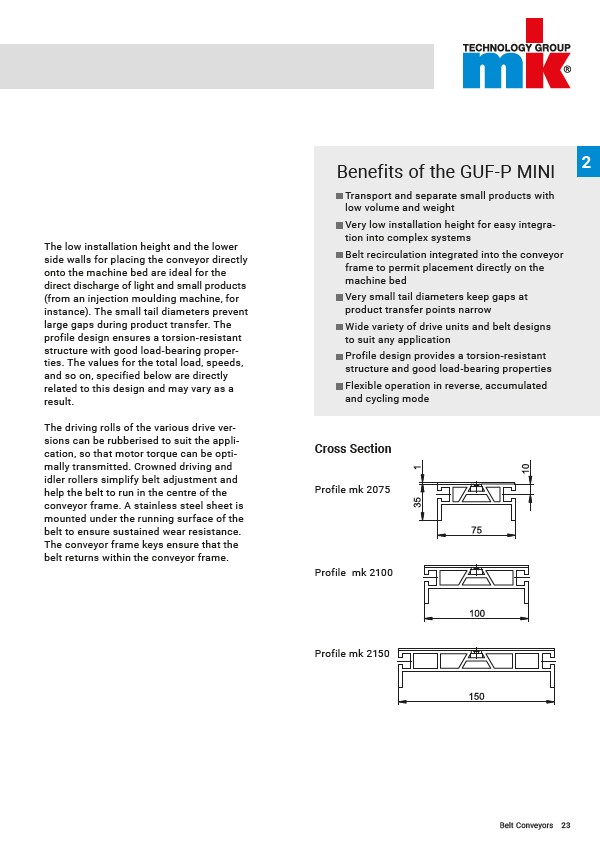

Cross Section

Belt Conveyors

Profile mk 2075

Profile mk 2100

Profile mk 2150