| | Item no. | Accu-

mulation | Material | Colour | Surface | Min. Ø

tail | Perm. temp-

erature | Approx.

belt thickness | Properties | Data sheet |

|---|

| GU-T0105-003BL | | | | | | | | | | |

|---|

| K1029003 | yes | PET | transparent | woven | 6 mm | -10 bis 70°C | 1,2 mm | laterally stiff,

antistatic,

FDA compliant,

oil resistant* | PDF |

|---|

| GU-T0101-008BL | | | | | | | | | | |

|---|

| K1029008 | yes | PET | transparent | woven | 20 mm | -10 bis 70°C | 1,3 mm | antistatic

FDA compliant,

suitable for curved

belt conveyor | PDF |

|---|

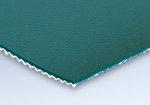

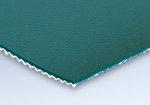

| GU-V0106-028DG | | | | | | | | | | |

|---|

| K1029028 | yes | PVC | green | smooth | 14 mm | -15 bis 80°C | 1,8 mm | Laterally stiff,

FDA compliant,

suitable for

incline conveyor | PDF |

|---|

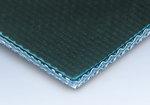

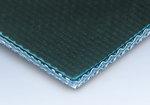

| GU-U0107-015DG | | | | | | | | | | |

|---|

| K1029015 | yes | PU | green | smooth | 40 mm | -10 bis 70°C | 1,6 mm | laterally stiff,

antistatic,

oil resistant* | PDF |

|---|

| GU-V0103-010SW | | | | | | | | | | |

|---|

| K1029010 | yes | PVC | black | smooth | 30 mm | -10 bis 60°C | 1,8 mm | antistatic,

suitable for curved

belt conveyor | PDF |

|---|

| GU-F0106-019SW | | | | | | | | | | |

|---|

| K1029019 | yes | felt | black | smooth | 30 mm | -10 bis 120°C | 2,5 mm | antistatic,

suitable for curved

belt conveyor | PDF |

|---|

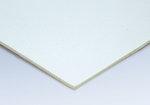

| GU-U0204-007WE | | | | | | | | | | |

|---|

| K1029007 | limited | PU | white | smooth | 6 mm | -30 bis 100°C | 1,3 mm | laterally stiff,

antistatic,

FDA compliant,

oil resistant* | PDF |

|---|

| GU-U0205-050LB | | | | | | | | | | |

|---|

| K1029050 | limited | PU | blue | smooth | 6 mm | -30 bis 100°C | 1,3 mm | laterally stiff,

antistatic,

FDA compliant,

oil resistant* | PDF |

|---|

| GU-V0203-006DG | | | | | | | | | | |

|---|

| K1029006 | Limited | PVC | green | smooth | 30 mm | -10 bis 70°C | 0,8 mm | laterally stiff,

antistatic | PDF |

|---|

| GU-U0205-011DG | | | | | | | | | | |

|---|

| K1029011 | limited | PU | green | smooth | 50 mm | -15 bis 80°C | 1,6 mm | laterally stiff,

antistatic,

FDA compliant,

oil resistant* | PDF |

|---|

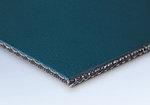

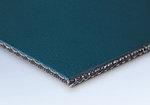

| GU-U0310-029G | | | | | | | | | | |

|---|

| K1029029 | no | PU | green | smooth | 50 mm | -30 bis 90°C | 2,4 mm | laterally stiff,

FDA compliant,

suitable for curved

belt conveyor,

oil resistant* | PDF |

|---|

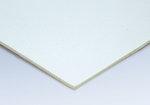

| GU-U0302-001WE | | | | | | | | | | |

|---|

| K1029001 | no | PU | white | smooth | 6 mm | -20 bis 70°C | 0,7 mm | antistatic,

FDA compliant,

oil resistant* | PDF |

|---|

| GU-U0305-004WE | | | | | | | | | | |

|---|

| K1029004 | no | PU | white | smooth | 6 mm | -30 bis 80°C | 1,2 mm | laterally stiff,

antistatic,

FDA compliant,

oil resistant* | PDF |

|---|

| GU-U0306-017WE | | | | | | | | | | |

|---|

| K1029017 | no | PU | white | smooth | 10 mm | -30 bis 80°C | 1,4 mm | laterally stiff,

antistatic,

FDA compliant,

oil resistant* | PDF |

|---|

| GU-U0308-030LB | | | | | | | | | | |

|---|

| K1029030 | no | PU | blue | smooth | 6 mm | -30 bis 100°C | 1,4 mm | laterally stiff,

antistatic,

FDA compliant,

oil resistant* | PDF |

|---|

| GU-U0305-024LB | | | | | | | | | | |

|---|

| K1029024 | no | PU | blue | smooth | 6 mm | -30 bis 100°C | 1,5 mm | laterally stiff,

antistatic,

FDA compliant,

oil resistant* | PDF |

|---|

| GU-U0306-012DG | | | | | | | | | | |

|---|

| K1029012 | no | PU | green | smooth | 25 mm | -30 bis 100°C | 1,4 mm | laterally stiff,

antistatic,

FDA compliant,

oil resistant* | PDF |

|---|

| GU-V0303-009DG | | | | | | | | | | |

|---|

| K1029009 | no | PVC | green | smooth | 25 mm | -10 bis 70°C | 1,8 mm | antistatic,

suitable for curved

belt conveyor | PDF |

|---|

| GU-V0307-013DG | | | | | | | | | | |

|---|

| K1029013 | no | PVC | green | smooth | 40 mm | -10 bis 60°C | 2,0 mm | laterally stiff,

antistatic | PDF |

|---|

| GU-R0303-005DG | | | | | | | | | | |

|---|

| K1029005 | no | NBR | green | woven | 30 mm | 0 bis 80°C | 1,5 mm | antistatic,

oil resistant*,

cut proof** | PDF |

|---|

| GU-U0305-016DG | | | | | | | | | | |

|---|

| K1029016 | no | PU | green | structured | 40 mm | -30 bis 80°C | 1,9 mm | antistatic,

oil resistant* | PDF |

|---|

| GU-V0306-014DG | | | | | | | | | | |

|---|

| K1029014 | no | PVC | green | structured | 50 mm | -10 bis 60°C | 4,9 mm | laterally stiff,

antistatic | PDF |

|---|

| GU-V0307-018SW | | | | | | | | | | |

|---|

| K1029018 | no | PVC | black | structured | 40 mm | -10 bis 60°C | 2,2 mm | laterally stiff,

antistatic | PDF |

|---|

|