SEW-EURODRIVE uses automated guided vehicles as mobile workbenches, with perfectly integrated belt conveyors from mk

Systematic Movement

As a specialist for conveyor technology, mk has many years of experience with the intralogistics of a wide range of industries. We develop and implement highly flexible components and transport systems for automated material flows, with a focus on short throughput times and high availability.

Solutions from mk

mk helps companies successfully shape their value stream, including their logistics processes. We offer optimised material flows and state-of-the-art transport systems that are undergoing constant innovation.

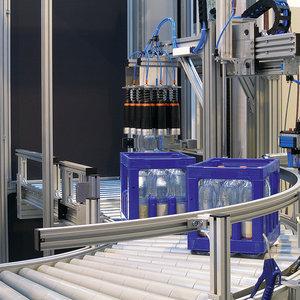

mk’s engineering expertise ensures that piece goods are provided, packaged or stored in the right location at the right time. Roller conveyors are the primary system used in this sector, where they serve as buffering and sorting lines for transporting pallets and crates of piece goods.

We also work with our partners and subsidiaries to offer state-of-the-art RFID and barcode technology as well as systems for measuring weight/volume and processing digital images.

Several platforms with stairs are required at a logistics centre belonging to the German armed forces. The platforms are intended to ensure safe and easy access to overseas containers that are stacked on top of one another. They need to be used across the entire site and therefore need to be on…

Assignment

A warehouse for wooden furniture panels was looking for a solution for picking, collecting and transporting the panels from the warehouse. Panels of differing sizes for each order needed to be conveyed ready for subsequent packing. Their dimensions varied greatly, from very small at…

Assignment

A warehouse for wooden furniture panels was looking for a solution for picking, collecting and transporting the panels from the warehouse. Panels of differing sizes for each order needed to be conveyed ready for subsequent packing. Their dimensions varied greatly, from very small at…

Problem definition

The customer sought to simulate the entire logistics process for consumer goods for use in a training centre. Using beverage crates as an example, the customer wanted to display all the various stations, from manufacture of the goods, to transport and storage, all the way to the…