Simulation of a Complete Logistics Process for Consumer Goods

Problem definition

The customer sought to simulate the entire logistics process for consumer goods for use in a training centre. Using beverage crates as an example, the customer wanted to display all the various stations, from manufacture of the goods, to transport and storage, all the way to the end consumer and the return of the empty containers. Maschinenbau Kitz provided the necessary conveyor technology and controling. This technology was to be supplemented with additional machines and models, in addition to constantly running presentations. The conveyor technology needed to represent the logistics processes as authentically as possible. An impressive access portal into the interior of the interlinked system was also required. All hazardous areas have to be guarded, so that visitors can not reach into the system.

mk Solution

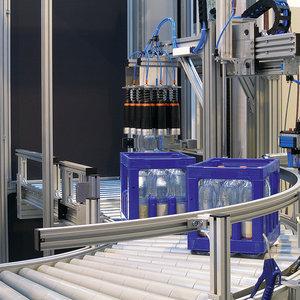

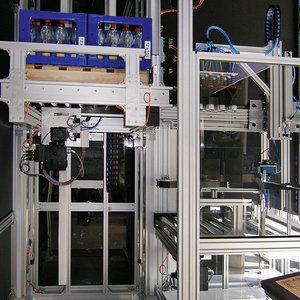

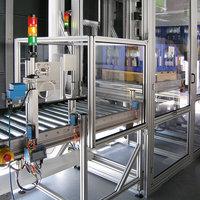

Complete circulation system for beverage crates. Transport from station to station using driven RBT-P 2255 roller conveyors in straight and curved versions. Simulation of a high bay warehouse with roller conveyors and a lift. Simulation of a forklift with a driven carriage on a track and a roller conveyor. Entry portal into the showroom with roller conveyors and a lift. Stoppers all along the interlinked system for pausing the beverage crates. Points for attaching customer-provided models and machines via the system slots of the mk profile construction kit. Guarding to prevent visitors from reaching into the systems and measures to reduce noise emissions. A control system with RFID chips on the boxes tracks the boxes and control the transfer systems.

Benefits to the customer

- Custom solution with mostly standardised components

- Adapted to the design and aesthetic requirements of the installation

- Low noise emissions

- Synchronisation of the conveyor technology with presentations and other machines

- Including complete assembly on site

- Including complete control and integration

Products

> Roller conveyors RBT-P 2255

> Linear modules LZR

> Guarding equipment

> Railing

> Aluminum profile series 40