Aluminium System Profiles and Connecting Elements for Maximum Flexibility and Reliability

Aluminium construction profiles are used wherever you build machine frames, workstations, shelves or guardings. Sturdy and flexible aluminium system profiles are also used for test set-ups, exhibit construction and load-bearing structures. You can find all the right aluminium profiles, connecting elements, accessories and tools with us.

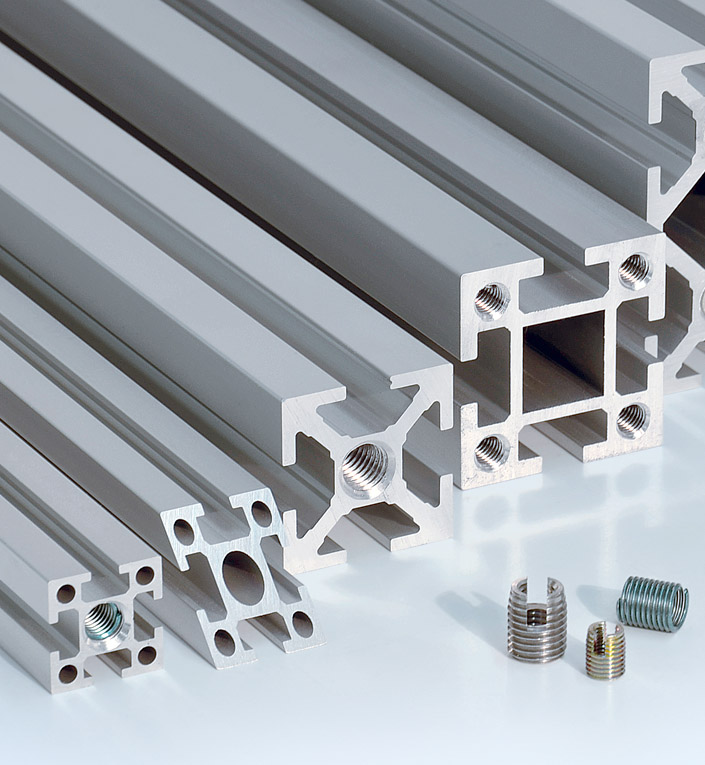

Aluminium System Profiles

The more than 200 high-quality system profiles provided by mk are divided into five profile series based on grid dimensions of 25, 40, 50 and 60 mm and a diameter of 28 mm. They meet all the requirements placed on aluminium construction profiles in mechanical engineering. Thanks to the huge selection of aluminium system profiles, you always have the right piece of the puzzle for your application and load and design requirements. With our aluminium profiles, you can create lightweight fixtures, machine frames or extensions just as effectively as load-bearing structures. Application profiles for special applications such as conveyor system frames are also part of the portfolio.

| Profile name | Grid dimension | max. Dimension | Material | Application examples |

|---|---|---|---|---|

| Profile Series D28 | ø 28 mm | ø 28 mm | AlMgSi 0,5 F25 | Supply trolley, shelves, lightweight frames, extensions for workstations |

| Profile Series 25 | 25 x 25 mm | 25 x 150 mm bzw. 50 x 50 mm | AlMgSi 0,5 F25 | Lightweight frames, cabinets, test set-ups, measurement and test units, electronics housings |

| Profile Series 40 | 40 x 40 mm | 160 x 160 mm | AlMgSi 0,5 F25 | Lighter machine frames, guardings, assembly workstations, exhibit construction, work platforms |

| Profile Series 50 | 50 x 50 mm | 50 x 200 mm bzw. 100 x 100 mm | AlMgSi 0,7 F28 | Heavy-duty machine frames, load-bearing structures |

| Profile Series 60 | 60 x 60 mm | 120 x 240 mm | AlMgSi 0,7 F28 | Machine frames for heaviest loads, gantries |

To achieve positive-locked connections, the ends of aluminium system profiles often need to be machined. Bolt fasteners, for example, require a suitable drill hole in the aluminium profile, and for special structures the profile ends may need to be mitre cut.

You can download free CAD models of profile and conveyor technology components from the mk Technology Group here.

Download CAD Data

Conveniently download free CAD models of profile and conveyor technology components from mk.

Download nowProfile Deflection Calculator

With our Profile Deflection Calculator, you can calculate the load-dependent deflection of aluminium profiles directly from here.

Calculate nowConnecting Elements

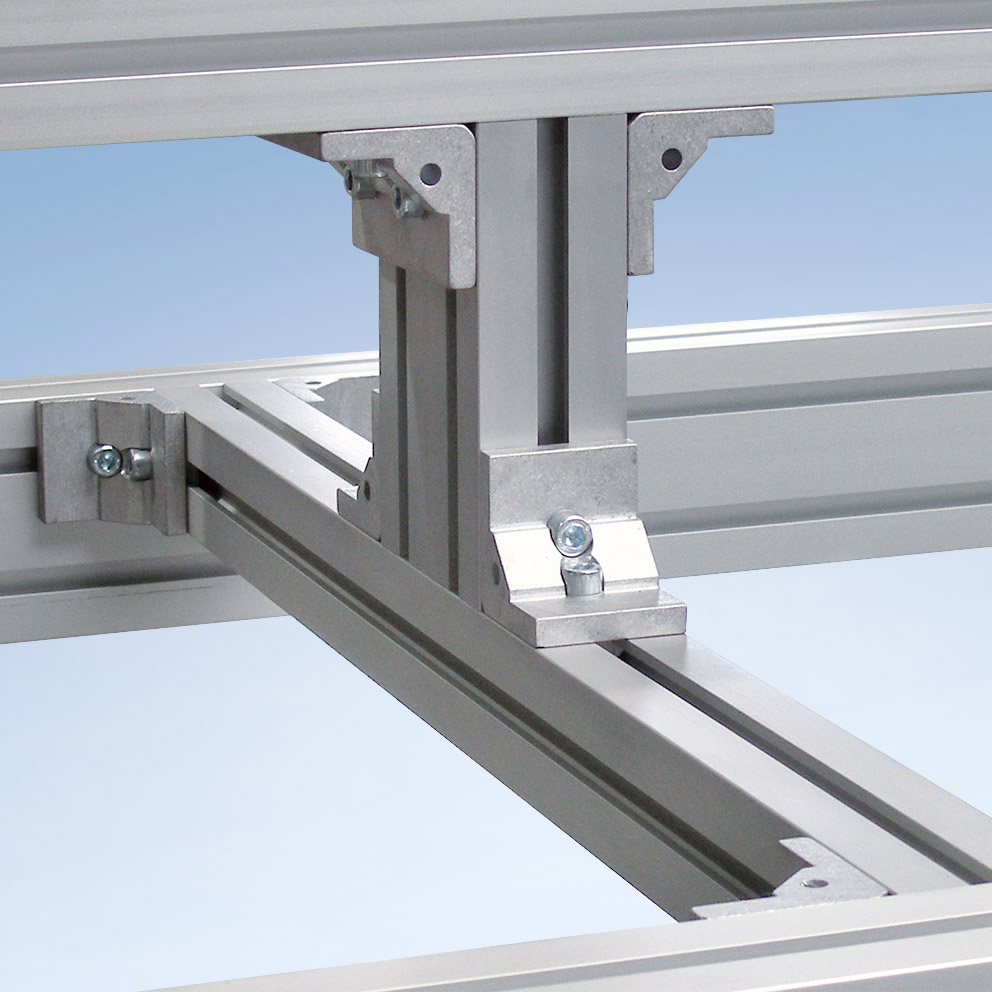

The extensive selection of connecting elements in the mk profile system ensures maximum flexibility and reliability in your aluminium profile designs. Whatever your requirements in terms of load capacity, twisting moment, ease of installation or design, our wide range of connectors will satisfy all your specifications and at any angle. All connecting elements use standard screws.

mk offers the perfect connection technology for every requirement. Whether it’s angle fasteners, internal fasteners, plate fasteners, corner fasteners, lattice connections or clamped connections, this page will show you which connection is right for your structure.

mk offers the perfect connection technology for every requirement. Whether you need angle fasteners, plate fastenings, internal fasteners, corner block joints or clamped connections, the following matrix provides a quick overview of which connector is suitable for your requirements.

1. How do I choose the right connecting element?

mk offers the perfect connection technology for every requirement. Whether you need angle fasteners, plate fastenings, internal fasteners, corner block joints or clamped connections, the following matrix provides a quick overview of which connector is suitable for your requirements.

The most frequently used connecting element for system profiles is the solid angle fastener. It is a simple, yet particularly sturdy screw connection. The angle is simply screwed into the slot of the aluminium profile using the corresponding DIN screw, the ribbed washer and the nut (T-nut). Apart from saw cutting, no profile machining is required for mounting.

Narrow or wide angles with short or long brackets and with two or more screws can be selected, depending on the requirements for stability and connection rigidity. This allows the connection to be installed, removed, moved and re-fastened at any time. The profiles can be easily repurposed thanks to the unused hole.

By working with metric DIN screws, the angles can be used to connect profiles from different mk series (25, 40, 50, 60) or other components to one another. Angle fasteners also form the interface to other aluminium profile systems or to steel construction.

Angle versions with key (indicated by an “s” in the product name: E25s, E40s, etc.) prevent undesired twisting and provide a perfectly aligned connection, even with only one screw per bracket. They also make it easier to set up rectangular structures.

Threads for fastening panelling can also be tapped into the side drill channels of the angles.

Almost all angles are available in the shop as a complete set. This includes the necessary fastening material (screws, ribbed washers, T-nuts/nuts) in appropriate quantities.

In addition to the 90° angles for the respective profile series, angle versions for custom requirements are also available:

- Angle brackets for structures with high static loads

- 30-45-60° angles for strut connections (reinforcing corners)

- Adjustable angle brackets for infinitely adjustable, static angles

2. What is the most commonly used connecting element for system profiles?

The most frequently used connecting element for system profiles is the solid angle fastener. It is a simple, yet particularly sturdy screw connection. The angle is simply screwed into the slot of the aluminium profile using the corresponding DIN screw, the ribbed washer and the nut (T-nut). Apart from saw cutting, no profile machining is required for mounting.

The following matrix shows an overview of the maximum load capacity of the screw connections. The values listed here for max. operating force and frictional connection include a safety factor of s0 = 2 compared with the max. values given in the literature. The information applies at room temperature for screws of strength class 8.8.

Safety factors

The following safety factors are recommended depending on the application:

Static or pulsating load: s0≥2

Changing load direction: s0≥3

Dynamic loads: s0≥4

Vibration and shock: s0≥5

3. How sturdy are the screw connections?

The following matrix shows an overview of the maximum load capacity of the screw connections. The values listed here for max. operating force and frictional connection include a safety factor of s0 = 2 compared with the max. values given in the literature. The information applies at room temperature for screws of strength class 8.8.

The following table serves as a rough guide as to how the pull-out strength changes with different profile-nut combinations, using the example of an M8 nut (nut 1, swivel-in nut 1, slot nut 1, T-nut 1) in series 40 and series 50 profiles.

Light duty and extra light duty profiles have a reduced pull-out strength, so longer nuts (nut 2, nut 3, etc.) should be used. Nuts that have a smaller contact surface compared to standard nuts also have a lower pull-out strength.

4. How sturdy are the nuts (T-nuts)?

The following table serves as a rough guide as to how the pull-out strength changes with different profile-nut combinations, using the example of an M8 nut (nut 1, swivel-in nut 1, slot nut 1, T-nut 1) in series 40 and series 50 profiles.

Angle fasteners and plate fastenings as well as profile clamps and anchor fasteners do not require any further profile machining apart from saw cutting. The connectors can be installed, moved or dismantled at any time. To mount all other connectors, one of the profiles is fitted with a thread or threaded insert on the front end and/or a side hole is required in the profile.

To reduce costs, extra light duty profiles include a central bore channel with a diameter D of 7.4 mm. This enables self-tapping screws to be screwed in directly. However, the assembly forces are quite high and screws with a special thread are required. We therefore recommend end machining with a thread or threaded insert, which means that all standard M8 screws can be used.

5. Which connecting elements do not require profile machining?

Angle fasteners and plate fastenings as well as profile clamps and anchor fasteners do not require any further profile machining apart from saw cutting. The connectors can be installed, moved or dismantled at any time. To mount all other connectors, one of the profiles is fitted with a thread or threaded insert on the front end and/or a side hole is required in the profile.

Constructions for cleanrooms or environments with high requirements in terms of technical cleanliness should be produced using cleanroom profiles. These environments feature a smooth and sealed surface, i.e. free from any slots, which prevents dirt from accumulating. In general, all internal connectors, including simple screw connections, tension plugs and, in particular, cleanroom fasteners and corner blocks are suitable for connecting cleanroom profiles. Using these connectors does not create any additional obstructing contours in the construction. Holes or open slots required for fastening can easily be covered with the appropriate plug or closure strip.

6. Which connector do I use for a cleanroom construction?

Constructions for cleanrooms or environments with high requirements in terms of technical cleanliness should be produced using cleanroom profiles. These environments feature a smooth and sealed surface, i.e. free from any slots, which prevents dirt from accumulating. In general, all internal connectors, including simple screw connections, tension plugs and, in particular, cleanroom fasteners and corner blocks are suitable for connecting cleanroom profiles. Using these connectors does not create any additional obstructing contours in the construction. Holes or open slots required for fastening can easily be covered with the appropriate plug or closure strip.

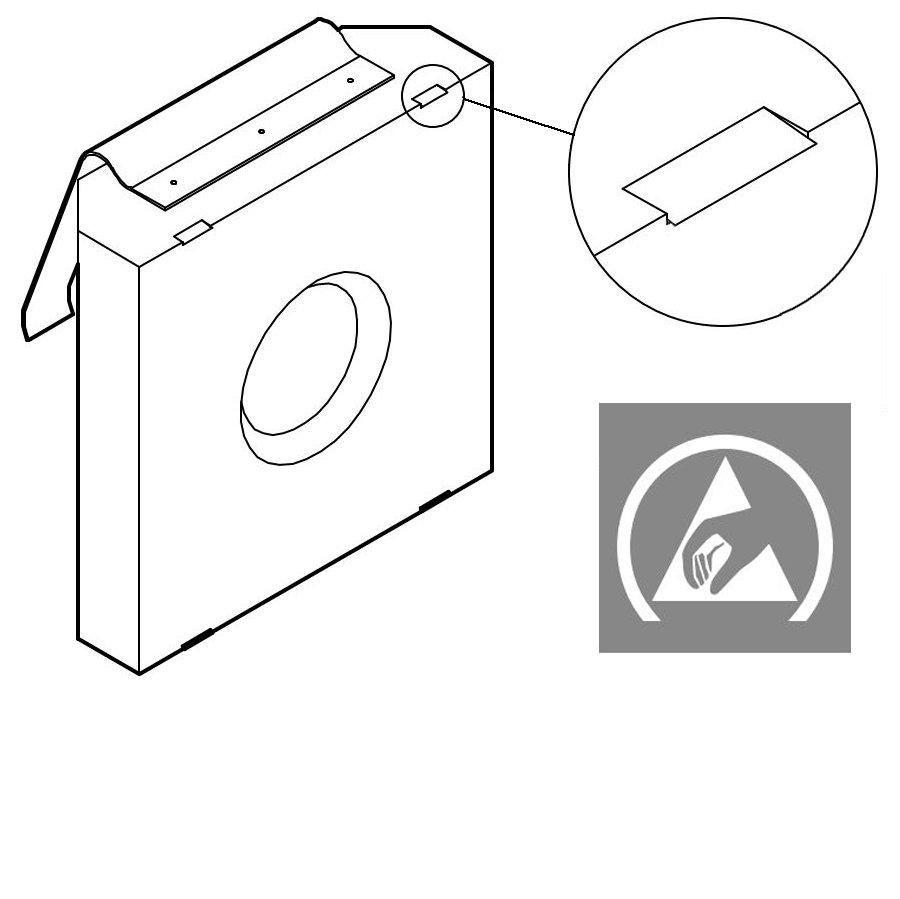

To create a conductive connection between the profiles, simply use the nuts/T-nuts marked with the ESD symbol. ESD nuts have an embossed design that penetrates the insulating anodised coating of the aluminium profile. The conductivity of the profile connection is therefore retained via the screw connection. If the construction is subsequently electrified, this means that the protective conductor only has to be connected to the aluminium profile construction in one location to provide earthing.

7. How can I protect a construction against ESD using connecting elements?

To create a conductive connection between the profiles, simply use the nuts/T-nuts marked with the ESD symbol. ESD nuts have an embossed design that penetrates the insulating anodised coating of the aluminium profile. The conductivity of the profile connection is therefore retained via the screw connection. If the construction is subsequently electrified, this means that the protective conductor only has to be connected to the aluminium profile construction in one location to provide earthing.

Screw connections allow users to create profile structures using only standard parts. The connection requires an M8 thread in profile 1 (extra light duty profile) or an M8 threaded insert. In profile 2, a ø10 mm bore is required at the spot of the connection to tighten the screw with an Allen key. For a seamless closure with an end cap, the bore should be 15 mm from the edge.

8. How do I connect aluminium profiles using only standard parts?

Screw connections allow users to create profile structures using only standard parts. The connection requires an M8 thread in profile 1 (extra light duty profile) or an M8 threaded insert. In profile 2, a ø10 mm bore is required at the spot of the connection to tighten the screw with an Allen key. For a seamless closure with an end cap, the bore should be 15 mm from the edge.

Angle fasteners and angle bracket connectors are easily screwed into the slot of the corresponding aluminium profile using the DIN cylinder head screws, ribbed washers and T-nuts included in the set. No profile machining is required for mounting. This allows the connection to be removed, moved and re-fastened at any time. Angles with a key prevent undesired twisting and provide a perfectly aligned connection.

9. How do I mount angle fasteners and angle bracket connectors?

Angle fasteners and angle bracket connectors are easily screwed into the slot of the corresponding aluminium profile using the DIN cylinder head screws, ribbed washers and T-nuts included in the set. No profile machining is required for mounting. This allows the connection to be removed, moved and re-fastened at any time. Angles with a key prevent undesired twisting and provide a perfectly aligned connection.

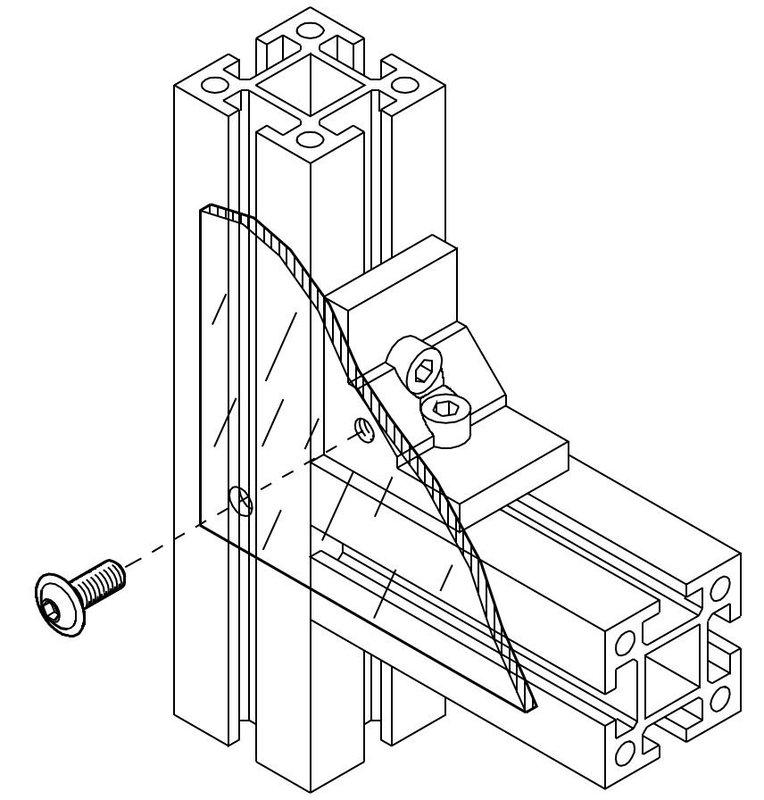

Tension plug B51.03.004 for series 40 is an alternative to the common angles when slots for inserting panelling need to be left free or when constructions are to be created without visible connecting elements. In profile 1, a ø 10 mm hole is required at a distance of 15 mm from the front end. The anchor is inserted into the central bore of profile 1 and fixed through the hole with the T-slot nut. The connecting anchor can now be inserted into the slot in profile 2 and tightened at any connection position with the threaded pin of the T-slot nut.

10. How do I mount the mk tension plug B51.03.004?

Tension plug B51.03.004 for series 40 is an alternative to the common angles when slots for inserting panelling need to be left free or when constructions are to be created without visible connecting elements. In profile 1, a ø 10 mm hole is required at a distance of 15 mm from the front end. The anchor is inserted into the central bore of profile 1 and fixed through the hole with the T-slot nut. The connecting anchor can now be inserted into the slot in profile 2 and tightened at any connection position with the threaded pin of the T-slot nut.

The tension plug B51.03.040 with thrust part for series 40 (normal and light) is an alternative to the common angles when slots for inserting panelling need to be left free or when constructions are to be created without visible connecting elements. Tension plug B51.03.040 allows a profile to be retrofitted, even if the faces of the second profile are already sealed. A ø 10 mm hole at a distance of 15 mm from the front end is required in profile 1 to be mounted. The T-slot nut is inserted into the hole. The anchor is inserted into the slot of the second profile at any connection position. The connector is fastened in the slot using the thrust part (ball with spring), which makes it considerably easier to mount attachment elements in a vertical position. The anchor pin is now inserted into the central bore of profile 1 and the threaded pin of the T-slot nut is tightened.

11. How can I retrofit the mk tension plug B51.03.040?

The tension plug B51.03.040 with thrust part for series 40 (normal and light) is an alternative to the common angles when slots for inserting panelling need to be left free or when constructions are to be created without visible connecting elements. Tension plug B51.03.040 allows a profile to be retrofitted, even if the faces of the second profile are already sealed. A ø 10 mm hole at a distance of 15 mm from the front end is required in profile 1 to be mounted. The T-slot nut is inserted into the hole. The anchor is inserted into the slot of the second profile at any connection position. The connector is fastened in the slot using the thrust part (ball with spring), which makes it considerably easier to mount attachment elements in a vertical position. The anchor pin is now inserted into the central bore of profile 1 and the threaded pin of the T-slot nut is tightened.

The anchor fastener is a profile connector that does not require the aluminium profile to be processed. It is slid into the ø10 mm bore of an series 40 aluminium profile and clamped using a screw. It is connected to the second aluminium profile via the side anchors and is therefore simultaneously secured against twisting.

12. How do I mount the mk anchor fastener?

The anchor fastener is a profile connector that does not require the aluminium profile to be processed. It is slid into the ø10 mm bore of an series 40 aluminium profile and clamped using a screw. It is connected to the second aluminium profile via the side anchors and is therefore simultaneously secured against twisting.

The tension plug S enables quick, strong and easy aluminium profile constructions without interfering contours. The ribbing on the contact surface ensures that the connections are conductive (ESD). Only minimal installation work is required: two screws for initial assembly, loosen and tighten one screw to move.

13. How do I mount the mk tension plug S?

The tension plug S enables quick, strong and easy aluminium profile constructions without interfering contours. The ribbing on the contact surface ensures that the connections are conductive (ESD). Only minimal installation work is required: two screws for initial assembly, loosen and tighten one screw to move.

Corner blocks allow three profiles to be connected to one another on the front end. Open corner blocks are secured using standard screws. This requires an M8 thread (extra-light profile) or an M8 threaded insert in the central bore of each of the profiles. Through the openings in the corner block, it is screwed into the threaded inserts of the respective profile.

14. How do I mount a corner block with open connector?

Corner blocks allow three profiles to be connected to one another on the front end. Open corner blocks are secured using standard screws. This requires an M8 thread (extra-light profile) or an M8 threaded insert in the central bore of each of the profiles. Through the openings in the corner block, it is screwed into the threaded inserts of the respective profile.

Corner blocks allow three profiles to be connected to one another on the front end. Closed corner blocks are secured using the included internal fastener. This requires a ø 10 mm bore in each of the profiles at a distance of 15 mm from the front end. The T-slot nuts are inserted into the bores. The tension plugs are screwed into the corner block and inserted into the respective central bore and the threaded pin of the T-slot nut is tightened.

15. How do I mount a corner block with a closed connector?

Corner blocks allow three profiles to be connected to one another on the front end. Closed corner blocks are secured using the included internal fastener. This requires a ø 10 mm bore in each of the profiles at a distance of 15 mm from the front end. The T-slot nuts are inserted into the bores. The tension plugs are screwed into the corner block and inserted into the respective central bore and the threaded pin of the T-slot nut is tightened.

End Caps, Wear Strips, Floor Elements, Tools and Accessories

The mk profile system offers an extensive range of functional, design, safety, mobility and stability components for completing your aluminium profile structure. As well as end caps, various covers and wear strips, you can choose from a variety of levelling feet, floor plates and rolls. Cover profiles, swivel joints and other functional accessories round off the profile system range. Tools and jigs for machining profiles supplement the range.

Download CAD Data

Conveniently download free CAD models of profile and conveyor technology components from mk.

Download nowProfile Deflection Calculator

With our Profile Deflection Calculator, you can calculate the load-dependent deflection of aluminium profiles directly from here.

Calculate now