A manufacturer of batteries for electric vehicles joins together individual round cells to make battery modules. The manufacturer would like these round cells to be inspected fully automatically in the goods receipt area.

High Reliability, Speed and Flexibility

Batteries and other electrical energy storage devices play a key role in the electromobility sector. They determine the reliability, power and price of a system to a large degree. The massive progress made in the field of e-mobility is seeing new production facilities for high-performance batteries springing up everywhere. mk is supporting this process with tailored, high-performance and cost-efficient solutions for plant interlinking.

The lithium-ion battery is currently the leading battery technology and is produced as a prismatic, cylindrical or “pouch” cell. These types of cell can be found in practically every battery application, from small electrical devices to stationary storage systems. However, their use in electric vehicles is deemed to be essential. Here, the individual battery cells are assembled into modules, then multiple modules are combined into battery packs, which are finally integrated into the vehicle. Following their use, they are fed into the reuse or recycling process.

Solutions from mk

Products from mk are used throughout the entire battery production process chain. From precise handling of individual cells to transporting complete battery packs, mk ensures the compatibility of the various production lines and thus smooth automation.

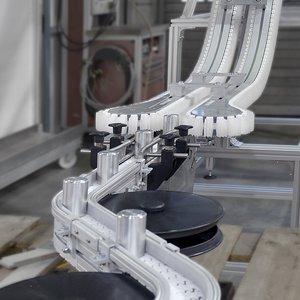

Starting at goods receipt, the individual cells must be delivered rapidly and dynamically for further processing. For the initial testing (reading the DMC code, cleaning, electronic and visual check, rejection of defective cells), the precise separation and positioning of cells is essential. Conveyor systems such as the mk Versaflex and mk Versamove ensure high cycle times with extraordinary precision, and without any electrostatic charging.

During the subsequent assembly of the cell modules into battery packs, a high degree of repeatability and positioning accuracy in a controlled environment is crucial. Likewise, tailored transfer and handling systems from mk ensure the safe integration of the finished battery packs, which can weigh up to 300 kg/m, into the vehicle.

Our subsidiary mkf efficiently handles further modules for assembly automation and testing technology tasks, as well as any cleanroom process steps. The experts at mkf also specialise in the field of cell production (mixing, coating, drying, separating, gripping or extracting vapours).

Round battery cells are fed into the assembly process for the production of battery packs and must be transported position-oriented to another level. The goods to be transported should flow smoothly, i.e. should be transported without a pallet, with maximum throughput and high process reliability.

Problem definition

Multiple machining stations needed to be interlinked for the production of electric motors for an electric sport utility vehicle. The stations needed to be interlinked across multiple levels. Lifts for lifting, lowering and turning are used to transport the pallets to the various…

Problem definition

A horizontal pallet recirculation system was needed for the production of electric motors for an electric sport utility vehicle. Together the workpiece and pallet weigh about 100 kg per pallet, which means a total load of 160 kg per meter of conveying path. The system needs to be…

Problem definition

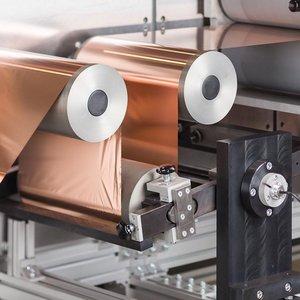

A modular and flexible process and systems concept was required for a research project. Metal foils needed to be coated with electrode material for the production of lithium-ion batteries. Aluminium or copper is used as the substrate, depending on whether cathodes or anodes are…

Problem definition

A process and a system for coating metal foils needed to be developed for a research and development project. The metal foils are used in the production of lithium-ion batteries. After coating, the foil must be dried before it can be calendered and rewound into a coil. The…