Faster transport of round battery cells in module building

Task

Round battery cells with a ø of 46 mm (80 to 120 mm in height) and a weight of 0.3 kg per unit are delivered to the incoming goods department of an automotive manufacturer for the production of battery packs. In the incoming goods department, the cells are sent to the assembly process in batches by robots and lined up on a belt conveyor.

The DMC code of the cells must be scanned on this belt conveyor. In addition, the cell should be cleaned, visually inspected and electrically tested in order to separate defective parts. The cells then have to overcome a height difference of approx. 2500 mm in a position-oriented, upright position in order to advance to the following process step.

The goods to be transported should flow smoothly, i.e. should be transported without a pallet, with maximum throughput and high process reliability.

Solution from mk

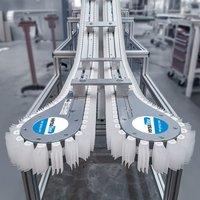

The Versaflex A06 flat top chain conveyor system is ideal for safely transporting the upright battery cells. In the horizontal sections, side rails with a clearance of 48 mm hold the cells upright and in the correct position for the subsequent process steps.

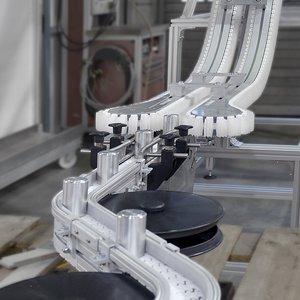

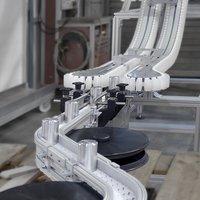

A clamping conveyor, also known as a double-grip conveyor, has proven to be the best solution for transport on inclines. Two Versaflex A06 conveying tracks directly opposite each other with flexible cams clamp the cells laterally and transport them vertically to another level. The conveyor climbs quickly and smoothly to a height of 3400 mm.

The conveyor speed is 480 mm/s (28 m/min), which corresponds to a cycle time of 0.1 seconds/unit or a throughput of 600 cells/minute. Including the horizontal sections before and after the incline, the conveying path has a total length of approx. 20 m. By using a clamping device, a large difference in height can be bridged over a relatively short distance with a steep incline.

Benefits for the customer

- Very fast, safe and smooth transport of the cells

- Easy adaptation to unfavourable spatial constraints

- Rapid assembly and disassembly thanks to profile design

- Interlinking with the entire system via interfaces that offer process reliability

Products used