Valibat Development Project – Process for Manufacturing Active Components for Lithium-Ion Batteries

Problem definition

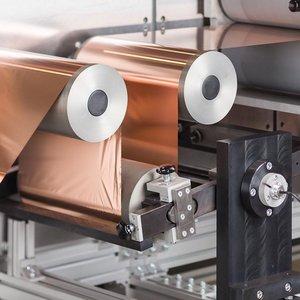

A modular and flexible process and systems concept was required for a research project. Metal foils needed to be coated with electrode material for the production of lithium-ion batteries. Aluminium or copper is used as the substrate, depending on whether cathodes or anodes are being produced. This requires expertise in multiple areas: material properties, coating processes, mechanical engineering, drying processes and calendering. The individual components were installed by our project partners: Fraunhofer IKTS, Suchy Textilmaschinenbau, Tridelta Thermprozess and our subsidiary mkf GmbH.

mk Solution

The project team developed castable electrode materials and a highly functional, modular coating machine that can be used to coat metal foils with fluid electrode material from roll to roll. The metal foils are unwound from a coil, coated, passed through an air flotation dryer, calendered and then rewound into another coil. The entire system ensures smooth and precise travel of the foil. A slot die or casting box can be used to apply the coating. The coils can be changed quickly and easily. The entire system has a modular design, consisting of a front end, five drying modules, an intermediate module, a calender and a back end. With a slot die, the coating can even be applied intermittently. The system is operated in the Competence Centre for Battery Technology at the Fraunhofer Institute in Hermsdorf/Thuringia, Germany. It is used to support further research and as a reference and demonstration system for users and other interested parties.

Benefit to the customer

- Collaboration with multiple areas of expertise

- Resulting in an innovative system

- Joint research and development with mutual exchange of knowledge between project partners