Feeding and buffering workpiece carriers in the tightest spaces

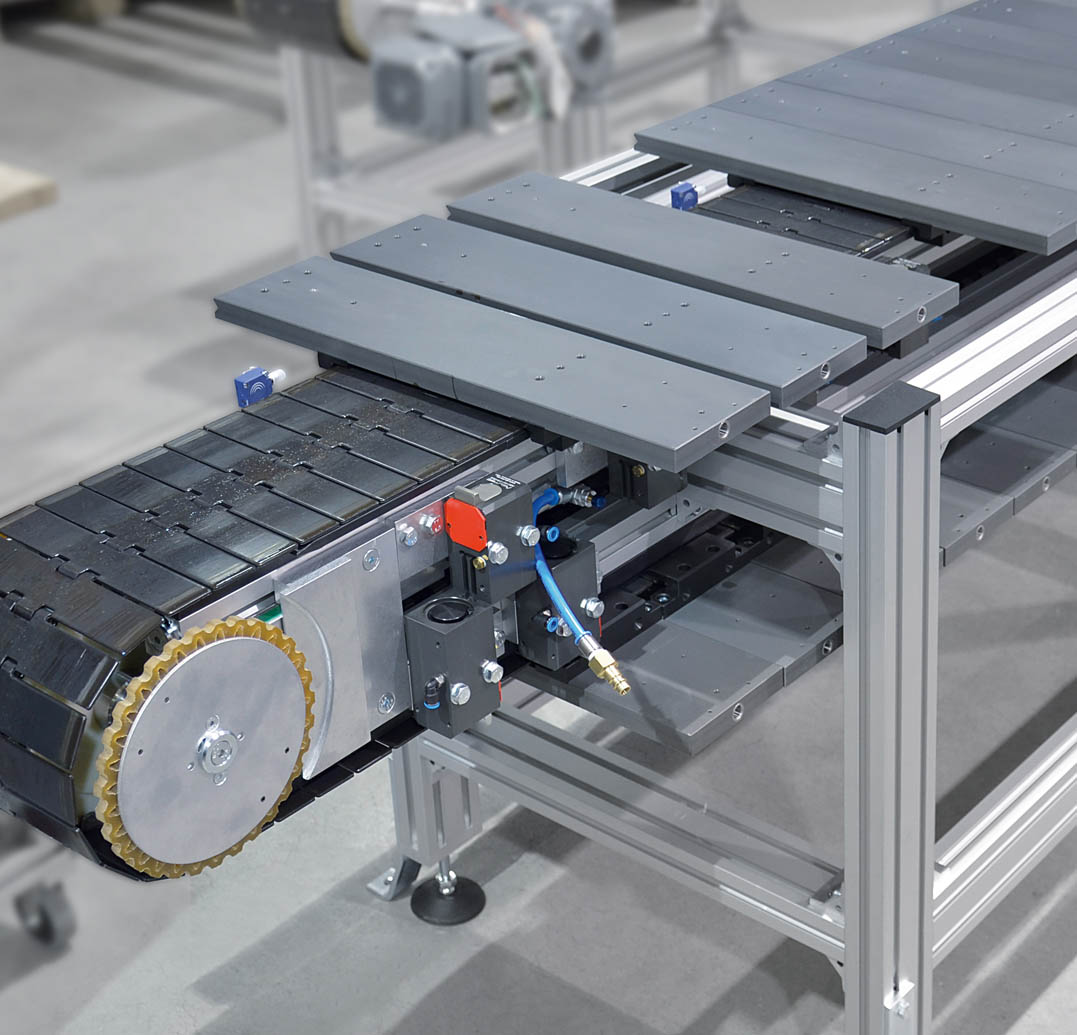

The SPU 2040 is an accumulating pallet recirculation system with automatic pallet recirculation for cost-effective and dynamic feeding, buffering, positioning and separation of pallets in the tightest of spaces. The system’s sturdiness and wide range of variants makes it suitable for virtually all automation and material flow applications.

The SPU 2040 allows for acyclic operation (i.e. independent of the infeed cycle) with automatic recirculation of the workpiece carriers. The workpieces on the workpiece carriers are transported by the flat top chain along the upper transport level. After the workpiece has been removed, the empty workpiece carriers are safely carried along in the tail and then conveyed back hanging below the transport level. They are then available at the start of the belt to be loaded with new workpieces. This eliminates the need for a second conveyor level or lift-and-lower units with complex control elements. It also eliminates the need to load the workpiece carriers on the belt, whether manually or automatically.

- Support plates made from aluminium plates or Series 40 aluminium profiles

- Lateral positioning slot and positioning socket ensure high positioning precision

- Pallet width for single and multi-line systems 160 or 236 mm. In double-line systems depending on the width of the conveyor. The standard length of a pallet is 160 mm.

- The max. permissible unladen weight depends on the type of system and the height of the workpiece holder

- Two drive types to the right or left of the conveyor line are available

- AF head drive direct, flange-mounted hollow shaft motor

- AC head drive indirect, gear motor with shaft journal

- Conveyor speeds between 4 to 15 m/min depending on the required cycle time of the pallets

- Vulkolan cleat pads ensure secure pallet transfer

- Electrical cylinder detection, optionally inductive available

- Detection of one or both switch settings of the stopper cylinder

- Lifting force = pallet + fixture + product + counter pressure max. 140 N (at 4 bar), max. 210 N (at 6 bar)Greater lifting force available depending on customer requirements

- Precise positioning of ±0.2 mm

The protective device guard at the tails minimises the risk of injury for the operator. A pendulum flap is triggered when touched and stops the entire system. A cover between the flat top chain and the frame is available on request. A protective device guard without a pendulum flap in profile design or as a sheet metal hood is also optionally available.

Contact

For custom requests, please contact our technical sales department at info(at)mk-group.com, by phone at +49 2284598-0 or using the contact form below.