Horizontal Pallet Recirculation in Accordance with Automotive Production Equipment Regulations

Problem definition

A horizontal pallet recirculation system was needed for the production of electric motors for an electric sport utility vehicle. Together the workpiece and pallet weigh about 100 kg per pallet, which means a total load of 160 kg per meter of conveying path. The system needs to be designed for later expansion. The entire interlink has to comply with the automotive manufacturer's production equipment regulations. This requires appropriate safety features and a maintenance-friendly design.

mk Solution

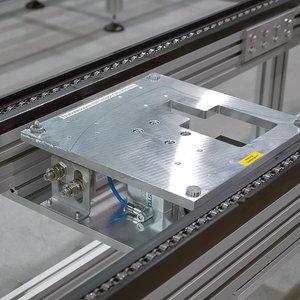

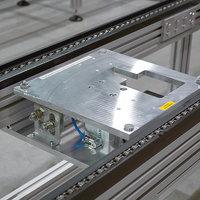

Versamove Plus recirculation system. The system is built from standard components from mk's system construction kit. This is advantageous in terms of both price and delivery times. The conveying paths employ SRF-P 2010 accumulating roller chain conveyors, which are particularly well suited for accumulated operation. Automatic tensioning devices which are prepared for use with a customer-provided central lubrication system simplify maintenance and repairs. Pneumatic positioning units along the path with a repeatability of +- 0.1 mm position the pallets to allow for automated handling of the workpieces. The system's corner transfer units have a pneumatic lifting motion for lifting and positioning the pallets. Timing belt conveyors then carry the pallets further along. The system, and the corner transfer units in particular, were designed with future expansion in mind to allow the conveying path to be extended. Approximately two years after delivery of the original system, mk also handled the expansion. The conveying path was extended and a second level was added, which is reached using lifts.

Benefit to the customer

- Complete pallet recirculation according to automotive production equipment regulations

- mk standard components used

- Easy integration into existing systems

- Quick and easy expansion of an existing system