Modular Belts

Modular belts, also known as plate belts, chain link belts or mat belts, for a wide range of conveyor applications.

Modular belts for MBF-P 2040 and KFM-P 2040

Series 8 is notable for its sturdiness and is used for transporting medium-weight to heavy products such as containers, bottles, boxes, etc. in industrial applications.

Series 10 is intended for transporting lightweight to medium-weight products in sanitary environments, such as those found in the food industry and the pharmaceutical sector. The module geometry and the sprocket wheels were therefore designed to ensure easy cleaning, to eliminate cavities and hollow spaces, and to allow for limited self-cleaning of the gaps.

Transverse cleats up to 75 mm in height and side plates up to 100 mm in height are available for both series. The side plates are available in heights of 25, 50, 75 and 100 mm and in the colours light blue and white. This eliminates the need for a complex side rail, as well as the associated problems arising from gaps and from relative motion between the chain and side rail.

The Series 8 chain made from impact-resistant, affordable polypropylene (PP) is the standard for industrial applications. Series 10 is made from polyethylene (PE) for applications in the food industry. For especially demanding requirements regarding max. load and/or cut resistance, we recommend polyoxymethylene (POM, POM-CR). This material can even handle the occasional impact from product landing forcefully on the chain or the transverse cleats.

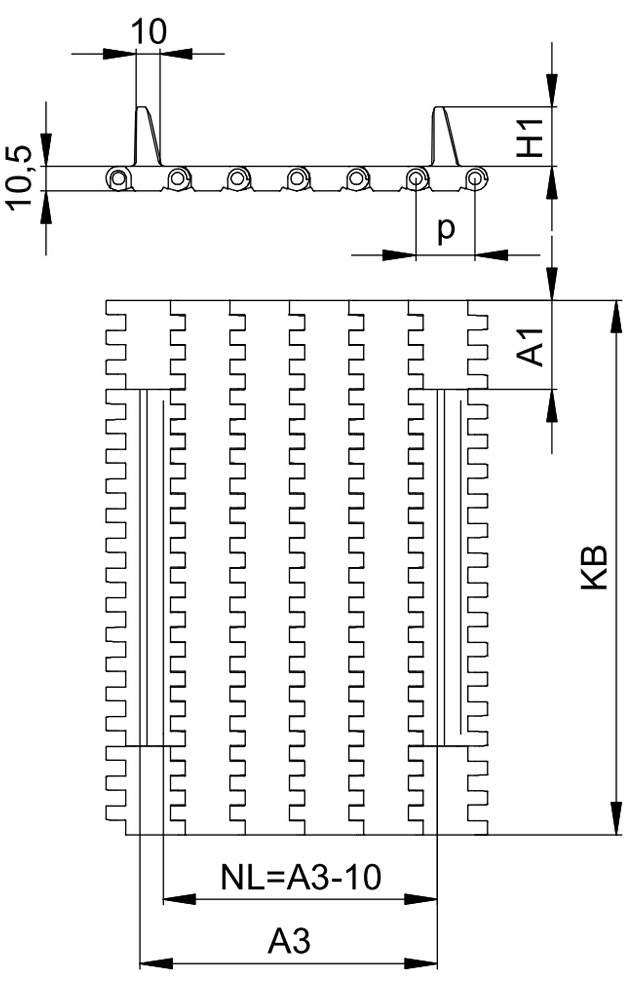

- Cleat height H1: 25.4 mm and 76.2 mm, others on request

- Cleat separation A3: in 25.4 mm increments

- Spacing p: 25.4 mm

- Modular belt thickness: 10.5 mm

- Min. edge clearance A1: 38.1 mm for KFM

- FDA/USDA suitability: partial

- Material:

PP: +5 to +100°C, colours: white, light grey

POM: -45 to +90°C, colours: blue

POM CR: -45 to +90°C, colours: anthracite

- Cleat height H1: 25 mm and 100 mm, others on request

- Cleat separation A3: in 25.4 mm increments

- Spacing p: 25.4 mm

- Modular belt thickness: 10.2 mm

- Min. edge clearance A1: 38.1 mm for KFM

- FDA/USDA suitability: FDA approval

- Material:

PE: -70 to +65°C, colours: white, light blue

PP: +5 to +100°C, colours: white, light grey

POM: -45 to +90°C, colours: white, light blue

Modular belt for KMF-P 2040 and hinged plate belt for MBF-P and KFM-P 2040.86

The modular belt ASB 2.2 is highly resistant to wear and abrasion, making it suitable for high temperatures, contact with chemicals or food, etc.. Other designs available on request, e.g. ESD or high portability.

The particularly robust hinged plate belt SK1 is also available in a stainless steel or perforated design on request.

- A1 (without / with side plate): 38,1 mm

- A2: 25 mm

- MB: 147-647 mm

- Cleat height H1: 20 / 40 mm

- Side plate height H2: 14 mm

- Cleat spacing A3: 38,1 mm in grid

- Spacing p: 38,1 mm

- Chain thickness: 13 mm

- Material / colour: Steel bright

- FDA/USDA-suitability: no

- Technical properties: Steel, wear-resistant, heat-resistant up to 300° C, resistant to impact, low friction coefficient

Contact

For custom requests, please contact our technical sales department at info(at)mk-group.com, by phone at +49 2284598-0 or using the contact form below.