Careful Transport of Chocolate Bars

Problem definition

During the production of chocolate bars, the bars are to be transported from the packaging machine to a downstream conveyor. There is only very limited space available. A height difference of around 480 mm and a 90° curve must be circumnavigated. During the vertical ascent, the chocolate bars must not slide backward even when the conveyor is stopped. The packaging of the chocolates is made of processed cardboard with a very delicate, velvety smooth surface. This must not be damaged. The chocolate bars must be smoothly transferred at the intersections of the conveyors.

mk solution

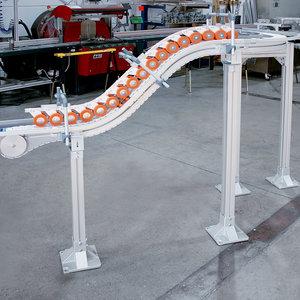

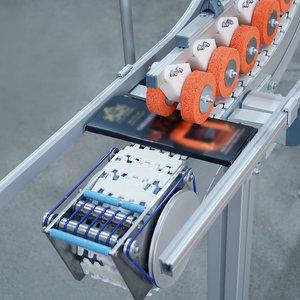

Variant A08 of the flat top conveyor system Versaflex was the ideal solution for the customer. Within a confined space, it transports the bars safely and gently to the downstream conveyor which is set at a higher level. The chocolate bars are held vertically on the chain by spring-loaded foam pressure rollers. A high friction coating on the chain provides a more secure grip. Round belt transfer points were positioned at the beginning and end of the conveyor. The transitions (loading and delivery of parts) are therefore kept to a minimum and are carried out as smoothly as possible.

Benefits for customers

- Perfect integration into the existing production system

- Quick and easy configuration and commissioning

- Cost-effective thanks to the use of standard components

Products