Ultra-fast production of lightweight components

Definition of the task

In the production of custom semi-finished products made of fibre-reinforced plastics (tailored composite blanks), individual layers of unidirectional fibre-reinforced coil material (known as UD tapes) are laser-welded to one another in different directions. As a result, individual reinforcement structures with a wide variety of geometries and layer structures can be manufactured. The Aachen Center for Integrative Lightweight Production AZL at RWTH Aachen University has developed a patented and award-winning process (JEC World Innovation Award, Paris 2019) to automate the laser-assisted laying of the tape in such a way that laminates can also be produced economically and on a large-scale. In order to be able to implement the process, AZL needed an experienced partner who understood how automation could be implemented and who could supply the relevant components.

Solution from mk

As an industry partner on the R&D project, mk worked with AZL to develop an automation line. The line conveys the pallets from deposit station to deposit station and also controls the feed rate in the process of laser-supported tape laying. mk was able to contribute its many years of experience in automation, conveyor technology and the handling of workpieces to the project and supply the right components.

The pallets are transferred by the Versamove pallet circulation system. Linear modules with timing belts provide the feed motion. These belts accelerate very quickly to meet the requisite accuracy and the speed requirement of 1 m/s. In order to achieve the required cycle time in the industrial process, two parallel linear units are used. The units work independently, at alternate times. The empty return stroke therefore takes place during the tape-laying machine’s non-productive time.

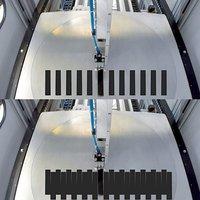

mk also supplied the protective housing for the project, which was designed as a protective laser enclosure. Labyrinth seals were used to eliminate any gaps with direct passage for light and lasers. During operation at AZL, it was found that extremely strong, reflected laser beams were able to escape as the pallet exited the laser cabin. A tunnel had to be added and the exit slot fitted with brush strips.

The project comprised two phases. In the first project stage, the feasibility was demonstrated using a functional prototype. In the second step, the system was expanded with an optimised station and a pallet circulation system in order to be able to implement fully automated production and to be able to further research the process.

Benefits for the customer

- Access to many years of accumulated knowledge in conveyor technology and automation

- Advice and delivery of the required conveyor technology

- Experience in project work in the R&D field

- Machines that can be flexibly expanded and modified

Products used

> Modified Versamove pallet circulation system

> Linear unit with recirculating ball bearing guide

> Protective laser enclosure