Unloading and sorting line for small load carriers

Definition of the task

In an automotive factory, empty small load carriers (SLC) are collected and cleaned at a central point (logistics centre), where they are then sorted according to size, type and design. The small load carriers are made from plastic and polystyrene. They vary in size from 200 x 200 x 100 mm to 980 x 580 x 200 mm and weigh a maximum of 5 kg each. The containers are delivered intermittently in quantities of approx. 1000 SLCs per hour.

A sorting line that can hold the large quantities of small load carriers and react to the different throughputs is now required. The load carriers will be placed on the conveyor manually by multiple workers and then manually removed again at the particular sorting station during ongoing operation. In addition to circulating and faster sorting, the aim is to design an ergonomic workflow and optimise the necessary personnel planning. The system is to be designed for three-shift operation.

In addition, the customer would like the investment to pay for itself within approximately two years.

Solution from mk

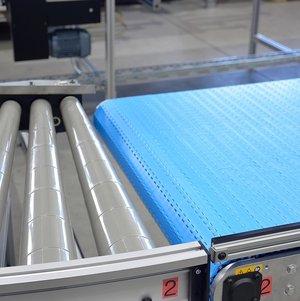

Together with the user, a large circulation system was constructed, resembling a luggage carousel in an airport. The small load carriers are transported in a circle so that they can be removed at the particular unloading position. The combination of MBF-P 2040 modular belt conveyors and RBT-P 2255 driven roller conveyors covers a conveying path of approx. 50 m on an area measuring approx. 18 x18 m.

The modular belt conveyor straights are extremely robust and low-maintenance as well as being very quiet during operation. Here, it is no problem to deposit or remove the small load carriers transversely to the conveying direction. Operators do not have to lift the carriers; they can simply be pulled down or pushed on at the level of the conveying surface. On the opposite side, a side rail is mounted as a stop to ensure that the small load carriers are loaded safely. In the event of damage, individual sections can be quickly replaced. The curves are designed as driven roller conveyors, which ensure optimal transport of the small load carriers. To guide the load carriers, guide rollers are installed on the approach to the curves and side rails on the way out.

To provide access to the inside of the circulation system, one of the modular belt conveyors provides maintenance access. The conveyor is mounted on fixed casters and can easily be pushed sideways out of circulation. If maintenance work is being carried out, partial segments can continue to be operated (emergency scenario).

Benefits for the customer

- Simple control for adaptation to different throughputs

- Assembly and start-up by mk service on site

- Perfect integration into existing processes

- Optimised for non-stop operation

Products used

> MBF-P 2040 modular belt conveyor

> RBT-P 2255 roller conveyor