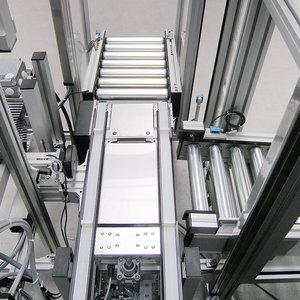

System for filling cardboard boxes

Problem definition

Design and production of a box filling machine for different tube formats of the cosmetics industry. Capacity: 200 tubes/min, 4 boxes/min. Chaining of upstream filling stations and integration of the provided scale with NOK outsorting of tubes. Chaining of box erectors from filling to further packaging. Counting of the specified tubes per box via light barriers, and checking the box fill quantity via an additional, provided scale with subsequent NOK separating box.

mk Solution

Complete system with inner open profile grooves for max. flexibility and outer closed grooves for a smooth, clean surface. Material handling of tubes and boxes with mk belt conveyors. Timing belt stations with timing belt conveyor, supported with pivot bearings for lowering for weighing. Funnel for accommodating a complete box fill quantity if there is a fault. In normal operation only pneumatically closed for box change.

Benefits to the customer

- Consulting and design by mk results in an optimal customer solution

- Comprehensive modular system extended with customer-specific functions

- Satisfies hygiene requirements

- A single source for assembly and installation including I/O modules in the control cabinet

Products

> Belt conveyor GUF-P 2000

> Timing belt conveyor ZRF-P 2040

> Roller conveyor RBS-P 2065/2066

> Cleanroom profiles series 40

> Guarding equipment

> Linear motion