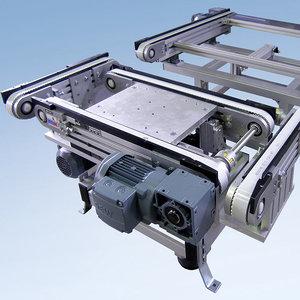

Turn Station with Lift-and-Traverse Conveyor for Packaged Food Products

Problem definition

In a food production application, stacked pallets need to be rotated by 90° and then further transported in the same direction so that they can be transferred to a buffer system. The pallets have a length/width ratio of 1 : 2.5, which is unfavourable for rotary motion. One pallet stack weighs 50 kg.

mk Solution

Lift-and-traverse conveyor with turn station consisting of two ZRF-P 2010 timing belt conveyors and a turn station. One timing belt conveyor has a pneumatic lift-and-locate unit. It is integrated perpendicularly in the space between the two lines of the second timing belt conveyor. An electrically operated rotary indexing table rotates the entire unit by exactly 90°. Another timing belt conveyor handles the transfer. The transfer conveyor can be moved forwards and backwards pneumatically. This is used to minimise gaps at the transfer point necessitated by the rotational clearance so that the pallets can be smoothly transferred. Side rails prevent the pallet stacks from tipping.

Benefit to the customer

- Reliable, precise rotation of unfavourable contours

- Rotation that does not require changing the conveying direction

- Unit for flexible use: product can be conveyed with both lateral and longitudinal orientation in three directions

Products

> Timing belt conveyor ZRF-P 2040

> Aluminum profile series 40