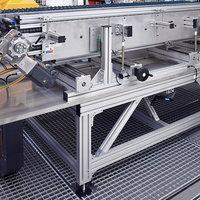

Flexible feed unit for varying workpiece dimensions

Task

Turned parts with a wide range of lengths (16 types) must be feed to a grinder. The feeding process must be performed horizontally and with only one belt conveyor. The workpieces are positioned by hand and removed by a gantry gripper provided by the customer. In order to keep the standstill times to a minimum, the conveyor must be able to be quickly adjusted to the respective workpiece dimensions. This requires a flexible two-line system that can be adjusted to the width and height of the workpieces for each line. After processing, the workpieces must be gently extracted without coming into contact with each other and without position accuracy.

mk solution

The feeding process is handled by two single line KTF-P 2040 chain conveyors with insertion prisms that each have their own drive and that are synchronised with each other. The distance between both conveyors, and thus also the width, can be adjusted via two synchronised adjusting units. The height of the conveyors is adjusted to the required workpiece height via a synchronised, hydraulic lifting cylinder. Furthermore, integrated adjustable side rails allow workers to make quick adjustments via the adjusting units. Thanks to hand cranks, the diameter, height and width can be quickly adjusted. The discharge belt was designed with a GUF-P 2000 belt conveyor with lateral cleats as dividers which allows the parts to be transported out of the work area. As fluids are handled during processing, every conveyor has its own drip pan.

Benefits for customers

- Conveyor system for various types of workpiece

- Greater efficiency thanks to short set-up times

- Large storage area for parts allowing extended autonomous machine operation

Products

> KTF-P 2040

> GUF-P 2000