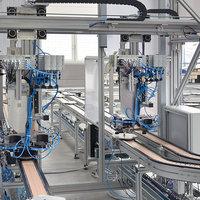

Flexible interlinking of production areas using flat top chain conveyors

Problem definition

In a production system for industrial filters, multiple, separate machining stations need to be interlinked. The interlinks should be as compact as possible. Products of different sizes need to be processed with minimal retooling times. The machine tools should also be able to adapt to the different products automatically. In addition to feeding and removal at the individual stations, the solution should include a drying line and a station for manual work, as well as a station that turns the products. Product accumulation and multi-product buffering must be possible.

mk Solution

Linear module with LZR 2000-38.41-25 timing belt as Z-axis – special design with Omega drive integrated on Y-axis

Benefit to the customer

- High degree of automation with proven mechanical components

- Products can be changed with no retooling time

- Two independent lines for failsafe operation

- RFID technology for automatically detecting and tracking products

- Little space required

- CE marking for the entire system

Products

> Flat top chain conveyor SBF-P 2254

> Linear module LZR

> Pallett

> Guarding equipment

> Aluminum profile series 40