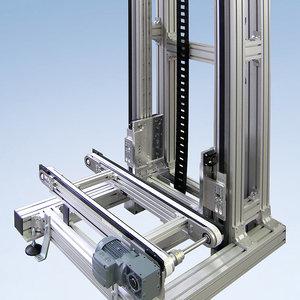

Lifts for Packaged Food Products

Problem definition

Stacked pallets in a food production application need to be lifted so that they can be buffered on multiple levels. Pallet stacks weighing 50 kg each need to be transported. The stroke length is approximately 3300 mm. The machine needs to lift and lower but also convey in order to feed the pallets into the buffer system.

mk Solution

Lift station with double LZR linear module with a timing belt as the conveying medium. The lift is driven by a servomotor with a brake. The motor is subject to torque monitoring for triggering safety devices such as brakes or shutdown switches. A timing belt conveyor for feeding pallets into the buffer system is mounted on cantilevers built from mk 2004 profiles. The lift and the timing belt conveyor are connected to a sturdy frame built from mk profiles, allowing them to stand alone without an additional support. Additional floor fasteners prevent tipping.

Benefit to the customer

- Large stroke for easy adaptation to spatial constraints

- Standalone solution for high flexibility

Used products

> Timing belt conveyor ZRF-P 2040

> Linear module LZR

> Aluminum profile series 40