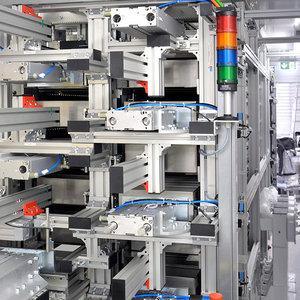

Mobile test bench with storage system

Problem definition

For a testing process, an entire system needs to be integrated into a maritime container so that the system can be used worldwide. Space is therefore extremely limited. A worker sorts the products to be tested into containers. The containers need to be conveyed into the system, shaken and then positioned so that a robot can remove a sample. After the sample is removed, the products need to remain in the storage area until the test procedure is complete. This takes about 45 minutes per sample. The product must then be discharged once the test result is in. Products must adhere to the first-in, first-out principle. It must be possible to uniquely assign the sample to the product from which it was taken.

mk Solution

Mobile test bench with storage system, built from the mk modular construction kit. GUF-P 2000 belt conveyors are used for the feeding and discharge lines. A GUF-P 2000 belt conveyor with a pneumatic clamp and an eccentric combined with two linear guides is used as the shaker. Pneumatic stoppers are used for positioning and achieve a precision of +- 0.2 mm. The storage system uses mk 2066 gravity roller conveyors arranged atop one another. One such assembly serves as the incline track, while a second, parallel assembly serves as the decline track. A pneumatic pusher pushes the containers from the incline track onto the decline track. Pneumatic pushers push the containers into the storage area and advance them one by one. A paternoster made from ZRF-P 2040.02 timing belt conveyors cycles the containers onto the individual storage levels. The containers are equipped with RFID chips so that the samples can be assigned to the product from which they were taken. The storage system has a capacity of 420 sample containers. The mk profile construction kit allows the entire system to be integrated into a maritime container, including the control cabinet and the guarding.

Benefit to the customer

- Extremely compact system with high storage capacity

- Gravity roller conveyors with permanently lubricated bearings for low maintenance

- Ergonomic and safe for workers

- Mechanical solutions with few drives for high reliability

- Includes complete electrical installation for start-up by the customer

- Also available in steel or stainless steel

Products

> Belt conveyor GUF-P 2000

> Timing belt conveyor ZRF-P 2040

> Roller conveyor RBS-P 2065/2066

> Guarding equipment

> Aluminum profiles series 40