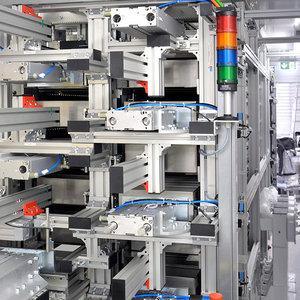

Paternoster built from timing belt conveyors

Problem definition

To feed and discharge containers from a multi-level storage system, the containers need to be raised to the various storage levels and then lowered again by a parallel storage line. The available space is very limited. The machine should be as reliable and require as little maintenance as possible. It should run in cycling operation at approximately 0.25 m/s.

mk Solution

Paternoster made from three parallel, vertically aligned ZRF-P 2040.02 timing belt conveyors. Cleats for the containers are mounted between the timing belt conveyors. One line cycles upwards, and the other line cycles downwards. The conveyors are driven by a single drive with a servomotor. The lines are connected to each other by a timing belt with teeth on both sides. An Omega drive is used to change the conveying direction.

Benefit to the customer

- Simple, mechanical solution for a highly reliable process

- Extremely compact

Products

> Timing belt conveyor ZRF-P 2040

> Aluminum profile series 40