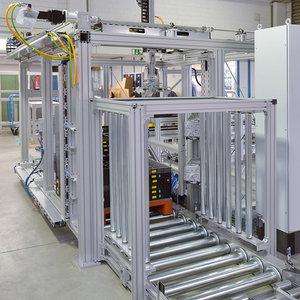

Three-Axis Handling with Heavy-Duty Roller Conveyor

Problem definition

The customer required a palletiser with a connected tray recirculation system: Pallet trucks are used to feed Euro pallets loaded with trays into the system and then remove them again at the end of the process. The palletiser destacks filled trays from the pallets and feeds them into the recirculation system. They are then conveyed to an index station, where a customer-provided robot removes the workpieces from the trays. The empty trays are conveyed back to the palletiser, where they are stacked on empty pallets and made available to be transported away. The system needs to be able to recognise and handle different tray types and different stack heights on the pallets. The machine needs to be built from components that are as tough as possible and be able to operate autonomously for up to 14 hours.

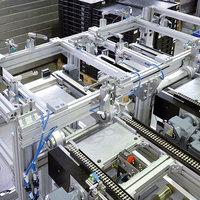

mk Solution

Profile-based transport system with feeding and removal of pallets via heavy-duty roller conveyors. Alignment of tray stacks using pneumatic positioning units with approach angle. 3-axis palletiser gantry, consisting of LZR 2005 linear modules with a rotating gripper and balancing stroke. Tray recirculation system, consisting of KTF-P 2010 chain conveyors combined with lifting units. Index station and device to hold down the trays so the workpieces can be removed by a customer-provided robot.

Benefits to the customer

- Fully automated system with reliable components

- Custom solution with cost-effective standard components and adapted special functions

- Supports direct loading and unloading with pallet trucks

- Individual trays can be buffered

Products

> Chain conveyor KTF-P 2010

> Linear module LZR 2005

> Roller conveyor

> Aluminum profile series 40

> Aluminum profile series 60