Tray Transfer and Handling System for IKLTs

Problem definition

For use with our patented, automation-ready reusable trays known as IKLTs (innovative small load trays), the customer requires a low-cost automation solution with semi-automatic transfer and an automatic unit for stacking and unstacking the trays from the base of the transport box. The products to be handled must remain in a defined – and therefore automation-ready – position throughout the entire value creation process. They need to be automatically filled, handled and then further processed in various process steps. The solution eliminates the need for sorting or repacking the products during production, storage and transport. The system allows for cost-effective, automated handling of even the smallest products.

mk Solution

The system consists of two independent modules, which can be used autonomously depending on your the application and requirements. This allows you to clearly see what you are investing in, and it gives the system the flexibility to respond to product changes or variations in order quantities.

Tray Transfer System

- GUF-P 2000 BF belt conveyor for product feeding, e.g. into an enclosed area, and to serve as a buffer line

- ZRF-P 2025 AC timing belt conveyor for timed positioning of the product for removal with an LZR 2000-38.41-15 two-axis pick-and-place unit

- Pneumatic lifting unit for return via a miniature, gravity-driven roller conveyor

- Small controller for the electrical drives and auxiliary drives and component monitoring from Infranor

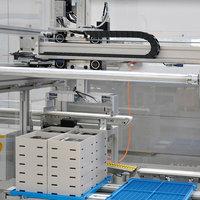

Tray Handling System

- Three-axis gantry with motorised linear modules and grippers and an Infranor controller

- Manual removal station for 2 boxes or with a conveying path (optional variant)

- Protective guarding with solid base frame

- Dual LZR 2004-38.41-30 linear modules with timing belt as X-axis base

- LZR 2005-38.44-30 linear module with timing belt and energy chain as Y-axis, Y-Z cross carriage with Omega drive as Z-axis

- LZR 2000-38.41-25 linear module with timing belt as Z-axis – special design with Omega drive integrated on Y-axis

Benefits to the customer

- Unstacking, feeding, removal and restacking – all in a single system without complicated control programming

- Defined interface with plug connections to connect the modules quickly and easily

- Minimal changeover times at the trays' loading and unloading positions

- Transport box to increase the tray capacity

- Optional expansion available for automated box feeding and removal

- Control applications can be created without any special knowledge of CODESYS programming (the functions for editing and testing the programs can be operated entirely from the HMI)

Products

> Belt conveyor GUF-P 2000

> Timing Belt Conveyors ZRF-P

> Linear Module LZR

> Aluminum profile series 40