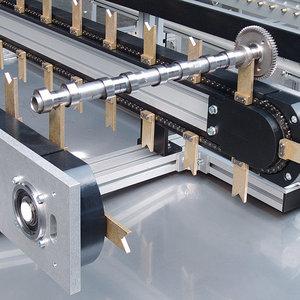

Indexing chain conveyor KTF-P 2040.02 as a raw parts conveyor

Problem definition

Camshafts are conveyed into a processing machine (lathe), separated and positioned, so that the camshafts are clamped into the processing machine identically every time. Since the aim is to process different types of camshafts, the width of the conveyor system must be variably adjustable

mk Solution

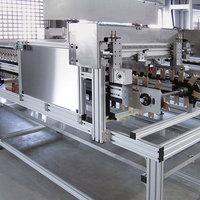

Prisms screwed to the chain serve as cleats for the camshafts. The drive shaft is loosely mounted in the second lane, making it possible to adjust the width using two linear modules. These are connected by a timing belt, so that they run in parallel and synchronously. A positioning unit at the end grabs and aligns the camshafts.

Benefits to the customer

- Low-maintenance, robust conveyor also suitable for dirty and hot environments

- Several product batches can be transported on one conveyor

- Prisms prevent product contact and associated material damage