Profile frames for demanding outdoor use

Task

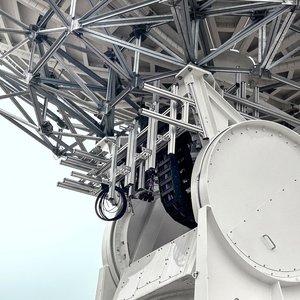

A manufacturer of antenna systems and radio telescopes needs a system to build substructures for control cabinets and the control cabins for these large antennas. The antennas are outdoors and are exposed to a wide range of weather conditions, such as wind, different levels of humidity, varying temperatures and even earthquakes. In the past, the substructures were made of steel. This proved to be too heavy and inflexible. The new system should have a modular structure in order to be as flexible as possible. The structures must be as light as possible, but at the same time must be able to reliably withstand the environmental conditions. The manufacturer will use the system to implement its own superstructures and attachments. The frames are covered with specially insulated plates. These plates provide additional rigidity and also protect the aluminium profiles from direct exposure to weather conditions.

Solution from mk

The mk aluminium profile system is ideal for the framework of the cabins. The modular design can be used to create any tailor-made construction or solution. Using the mk specifications such as area moments of inertia and moments of resistance, the customer is able to implement its own constructions. A structural engineer commissioned by the customer confirmed that the profiles and connections with the correct tightening torques can safely absorb the loads. Thanks to the anodised coating of the profiles and the use of stainless steel screws for the connections, the constructions are also protected against corrosion. The use of ESD nuts ensures a grounded construction.

Benefits for the customer

- flexible due to the use of screwed aluminium profile technology

- suitable for demanding outdoor use thanks to anodised finish

- high security due to appropriate dimensioning

- high stability and yet lightweight

- easily expandable by adding or moving the connection points

- individual design thanks to the modular design principle

Products used