Protection for sensitive products

Task

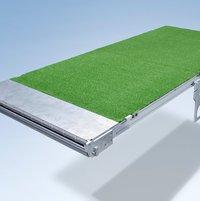

Extremely sensitive products can be damaged simply by being placed on conveyor technology. This is true both for very light and fragile products as well as for heavy and vibration-sensitive products. In this case, the products had a diameter of between 50 mm and 300 mm and a weight ranging from 50 g to 10 kg. They were placed on the belt conveyor by robots and other conveyor technology as well as manually. A solution was needed to minimize the shock to the products when setting them down on the conveyor.

Solution from mk

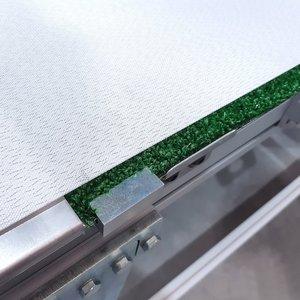

As a rule, the running of the conveyor belt between the two rollers on a belt conveyor is supported at the end by a stainless steel sheet. In this case, instead of the slide bed, the belt support was realised using a type of artificial turf. This ensures that the products are cushioned when they are set down on the belt. Despite the friction created between the artificial turf and the belt, mk was able to prevent the belt from becoming statically charged, ensuring that accident prevention regulations and machine safety requirements continue to be met. mk also succeeded in maintaining stable tracking thanks to the special conveyor design. The sensitive products can be set down gently without tipping over. Rolling knife edges with a radius of 19 mm are also used on the infeed and discharge ends. The small transfer gap means that even the small products with a diameter of 50 mm can be safely conveyed and transferred.

Benefits for the customer

- Gentle product transport

- Stable tracking and accident prevention regulations still ensured

Products used