Die Firma rebuy errichtete eine komplett neue Pilotanlage zur automatisierten Überprüfung und Aufbereitung von Smartphones. mk lieferte hierfür Förderstrecken und Arbeitsplätze.

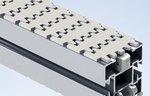

Der flexible

Kunstoffkettenförderer

aus dem Baukasten

Das komplett modulare und standardisierte Kettenfördersystem Versaflex mit Kunststoffkette, eignet sich ideal für komplexe Streckenverläufe im dreidimensionalen Raum. Mit verschiedenen Kettenbreiten können Anlagen schnell projektiert und problemlos aufgebaut werden, alternativ auch mit Werkstückträgern.

Das Kunststoffketten-Fördersystem Versaflex ist nach dem Baukastenprinzip aufgebaut. Dank der standardisierten Module und Komponenten kann es einfach und kostengünstig in jeden Produktionsprozess integriert, angepasst und erweitert werden. Versaflex ist ein Fördersystem, das mit Ihrer Aufgabenstellung mitwächst.

Ob als schlüsselfertige Lösung für den Endanwender oder als Funktionsmodul für den Maschinenbauer oder Integrator. Der Aufbau, die Erweiterung und Anpassung aufgrund veränderter Anforderungen ist durch das modulare Prinzip schnell und kostengünstig möglich.

Zudem ist es kompatibel zu am Markt bestehenden Scharnierketten-Systemen und in sämtlichen Bereichen der Industrie sehr erfolgreich im Einsatz. Insbesondere für den Transport von primär und sekundär verpackten Erzeugnissen unter anderem aus der Lebensmittel-, Pharma-, Chemie-, oder Konsumgüter-Industrie, aber auch für den Transport von Werkstückträgern in Montagelinien z.B. der Automobilindustrie und zur Verkettung von Maschinen in der produzierenden Industrie ist das System optimal geeignet.

Systemüberblick Versaflex

Dank des einspurigen Aufbaus und Kurvenradien ab 150 mm können komplexe Streckenverläufe im dreidimensionalen Raum abgebildet werden. Die Kunststoffkette läuft verschleißarm auf Gleitleisten und kann im Standard mit nur einem Antrieb mit Geschwindigkeiten von bis zu 50 m/min und Systemlängen bis zu 40 m betrieben werden.

Neben den Förderstrecken komplettieren zahlreiche Module und Komponenten den System-Baukasten und geben konstruktive Freiheit bei der Auslegung des Scharnierkettenförderers. Passend zum Transportgut und der Aufgabenstellung bietet das Versaflex-Kettenfördersystem Antriebe, Bögen und Mitnehmer, sowie Seitenführungen und Ständer an. Zudem stehen Funktionsmodule wie Stopper zum Stauen, Puffern oder Vereinzeln und Weichen zum Verteilen der Produkte auf mehrere Förderspuren zu Verfügung. Zudem kann das System zum Transport von Werkstückträgern ausgelegt werden.

Förderketten Versaflex

Das Produkt kann bis zur dreifachen Breite der Kette breiter sein, solange der Schwerpunkt des Transportgutes auf die Kettenmitte fällt, ggf. sind zusätzliche unterstützende Führungsschienen und Seitenführungen erforderlich.

| Kettenbreite [mm] | Systembreite [mm] | Produktbreite [mm] | max. Produkt- gewicht [kg] | max. Gesamt- last [kg] | max. Förder- länge [m] | max. Geschwin- digkeit [m/min.] | ||

|---|---|---|---|---|---|---|---|---|

| Versaflex A06 |  | *63 mm | 65 mm | 15-140 mm | 10 kg | 150 kg | 40 m | 50 m/min. |

| Versaflex A08 |  | *83 mm | 85 mm | 20-200 mm bis 150 mm (P08) | 15 kg 10 kg (P08) | 200 kg | 30 m | 50 m/min. |

| Versaflex A10 |  | *103 mm | 105 mm | 25-300 mm | 20 kg | 200 kg | 30 m | 50 m/min. |

| *Weitere Kettenbreiten sind auf Anfrage verfügbar. | ||||||||

Die Ketten bestehen aus dem Material POM und sind in den unterschiedlichsten Ausführungen für nahezu jede Anwendung verfügbar. Mit Haftoberfläche für Steigungen, mit Stahlbelag für scharfkantige Teile oder beflockt für den besonders sanften Transport. Daneben wird eine Vielzahl von verschiedenen Mitnehmern angeboten. Rollen in unterschiedlichsten Dimensionen zum Stauen oder flexible Mitnehmer zur Realisation von Klemmförderern. Zudem können Kettenglieder mit eingelassenen Magneten zum Transport magnetisierbarer Teile genutzt werden.

Versaflex als Werkstückträger-System P08

Für eine exakte Positionierung von Produkten können auf dem System A08 zudem Werkstückträger transportiert werden. Das System hat, wie oben beschrieben, eine Breite von 85 mm (Kettenbreite 83 mm) und ist für Produkte mit einem Gewicht bis max. 10 kg pro Werkstückträger ausgelegt. Die Werkstückträger haben im Standard eine Breite von 150 mm und werden mithilfe der Seitenführungen geleitet und in den Fixierstationen exakt in drei Ebenen positioniert. Schonend, sicher und genau werden so die Produkte fixiert, gepuffert und transportiert.

Der Werkstückträger kann kundenspezifisch angepasst werden und mit individuellen Aufnahmen bestückt werden. Die Fixierstation kann ohne Änderung der Seitenführung frei positioniert werden. Es wird eine Positionsgenauigkeit von ±0,1 mm erreicht. Der WT wird dabei von der Förderkette abgehoben.

Anwendungsbeispiele für Versaflex Kettenfördersysteme

Batterie-Rundzellen werden zur Fertigung von Batteriepacks dem Montageprozess zugeführt und müssen lageorientiert auf eine andere Ebene transportiert werden. Das Transportgut soll im Fluss bleiben, d.h. ohne Werkstückträger, mit maximalem Durchsatz und hoher Prozesssicherheit transportiert werden.

Aufgabenstellung

Für die Produktion von kleinen Getriebeteilen muss ein Förderer die Teile von der Produktion zur Kontrollvorrichtung transportieren. Alle zehn Sekunden soll ein Teil aufgegeben werden. Die Anlage läuft im 2-Schicht-Betrieb. Um in die vorhandene Anlage hineinzupassen, muss der…

Montage eines Versaflex-Förderers

Anfrage

Für eine individuelle Anfrage nutzen Sie bitte das folgende Kontaktformular oder kontaktieren Sie jederzeit unseren technischen Vertrieb unter info(at)mk-group.com oder per Telefon +49 2284598-0.