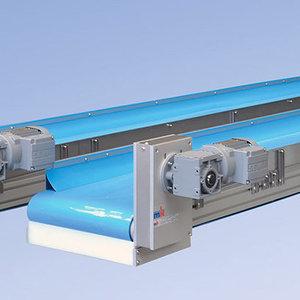

Belt Conveyor for Granules in the Food Industry

Problem definition

Unpackaged granules need to be transported in a food production application. The conveyor technology needs to provide constant transport in a straight line; there are no requirements regarding the position or orientation of the product being conveyed. The system is part of the main production flow. Applicable food production regulations must be adhered to.

mk Solution

GUF-P 2041 belt conveyor with sanitary and easy-to-maintain timing belt drive. FDA and HACCP-compliant belt with ribs on the running side for a positive drive mechanism. Matching sprocket wheels in the drive and tail prevent the belt from slipping or shifting. Blue belt for early detection of abrasion particles in the product. Fixed SF2.1 side rail with belt seal to prevent granulate from getting between the belt and the side rail. Wiper at the belt discharge end. Conveyor frames based on mk 2251 profiles with closed system slots. Anodised aluminium parts, A2 steel parts. The belt conveyor nearly meets the requirements for mk’s “FDA+” corrosion-resistant design.

Benefit to the customer

- Design according to customer requirements

- Sanitation standards for transporting unpackaged food products

- Timing belt drive for ease of maintenance

- Also available in stainless steel for stricter sanitation standards