Conveyors with Steel Belts as the Transport Medium

Task

In the production of plastic plates, blanks are fused together in an oven to create one homogeneous plate. The vacuum oven reaches temperatures of over 100 °C and produces a chemically aggressive atmosphere due to the evaporation of the plastics.

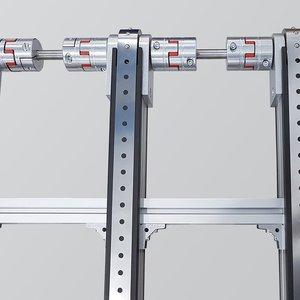

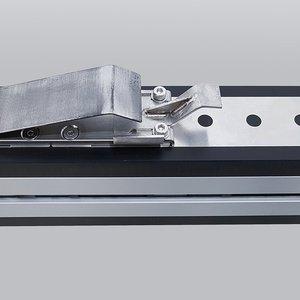

To automate the process, the manufacturer wants to use a feeding and removal system consisting of multiple levels for the furnace. Each level is to be equipped with a three-line conveyor to ensure that the plates can be fed into the furnace simultaneously and fused, thus achieving a high throughput rate. The conveyors are mounted on a swivelling device that can swivel the conveyors to the front of the furnace and back again in a short time. A reverse motion with high acceleration is required to pick up the products and deposit them in the furnace. A special cam provides a positive fit between the conveying medium and product that ensures safe ejection.

The conveyors need to withstand the temperatures in front of the furnace and must be resistant to chemically aggressive vapours.

Solution from mk

An mk three-line conveyor based on an mk ZRF-P 2040 timing belt conveyor with a stainless steel belt (from Belt Technologies) is installed as a transport medium on each level. The steel belt is perforated and is positively driven by cams on the drive. This makes the movement very precise, especially during high acceleration and continuous reverse operation.

The conveyor is designed for the high temperatures produced when the furnace is opened at the entrance and for the hot products. The choice of special wear strips combined with the stainless steel belt ensures both temperature resistance and high resistance to aggressive vapours. The solution also uses temperature-resistant VA bearings.

Benefits for the customer

- Customer-specific solution for special environmental conditions

- Expert consulting thanks to our knowledge of the field of handling

- Modular construction kit

Products used

> No standard products

> Custom adaptation based on the mk construction kit system