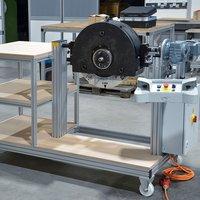

Profile frame with motorised turning device

Task

A mechanical engineer in the plastics industry uses a large number of different grinding wheels with different contours for grinding the corresponding extruder nozzles. Depending on the nozzle, the grinding wheel has to be changed up to once a day. The heavy wheels, including the casing, are lifted out of the grinding machine using a cargo crane. To change the wheel, the horizontal casing must be turned manually several times. A mobile turning device is now required to facilitate this arduous changing process. The turning device should be designed for a maximum rotating mass of 220 kg.

Solution from mk

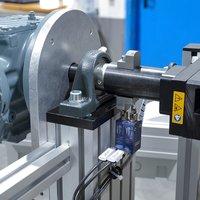

A frame was constructed from series 40 aluminium profiles in which the grinding wheel can be easily rotated into position and changed. To do this, the casing together with the grinding wheel is hung in the fixture and locked in place using a cargo crane. It can now be rotated by 180° in reversing mode. The turning motion is motorised using a gearmotor. To prevent overturning, the two end positions 0° and 180° are queried via roller switches. The movement is controlled using a two-handed control device with a control panel.

In addition, the fixture has multiplex shelves for additional grinding wheels, spare parts or tools and is designed to be mobile with fixed and swivel casters. The controller with FI is completely installed and wired ready for connection.

Benefits for the customer

- More efficient production due to a reduction in changeover times

- Reduces the strain on employees with individual solutions

- Mobility thanks to mobile frame

Products used

> Series 40 aluminium profiles

> Machine frames