The customer requires a pallet circulation system for the production of gate valves for water pipes, on which the valves can be assembled and buffered. The system then needs to transport the valves to the customer’s dipping station where they are checked for leaks.

Modular Transport Systems for Fully Automatic Interlinking of Processes

In order for a machine to function as a whole, the individual production steps must be efficiently interlinked. mk transfer systems, which work perfectly with the system controller and modern testing technology, feed, discharge, buffer, separate and position workpieces and pallets.

With proven mk transfer systems, you are getting reliable and practical interlink solutions that will optimise your production and assembly process – all the way from the unmachined part to the verified finished part.

Whether as a parts buffer between individual processing steps or as feeder to automatically recognise and separate faulty parts, mk transfer systems can be seamlessly integrated into every production design.

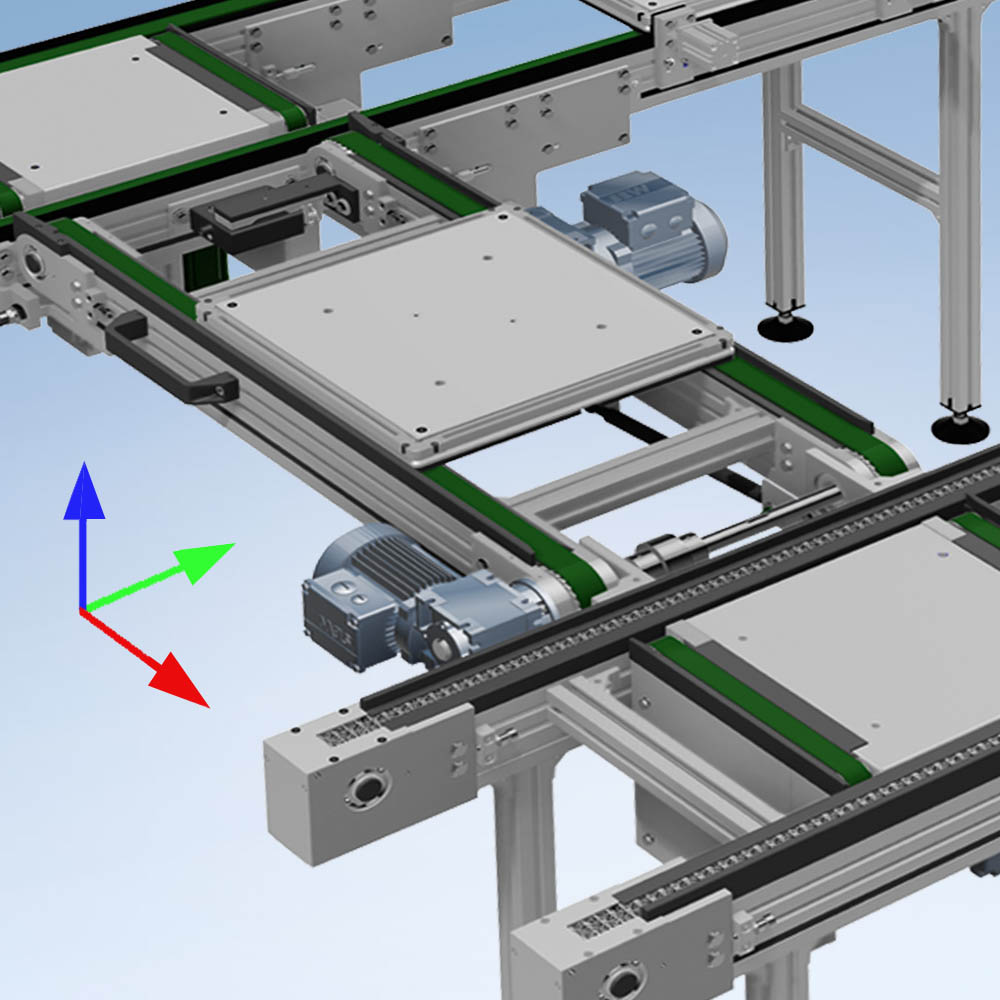

We can plan, design and install custom and fully networked transfer systems, including the necessary controllers, using our standardised Versamove, SPU and TKU pallet systems as well as our modular Versaflex flat top chain conveyor system. All mk transfer systems have a modular design and are thus flexible and scalable to customer requirements. In addition, they allow for quick scheduling and project planning and are easy to expand and reconfigure.

mk guides you through the entire product life cycle upon request – from the consulting and conception phase, through design and realisation, all the way to on-site start-up and subsequent maintenance. A lead project manager remains informed of all project activities at all times to ensure smooth and effective communication.

A manufacturer of batteries for electric vehicles joins together individual round cells to make battery modules. The manufacturer would like these round cells to be inspected fully automatically in the goods receipt area.

SEW-EURODRIVE uses automated guided vehicles as mobile workbenches, with perfectly integrated belt conveyors from mk

Contact

For custom requests, please contact our technical sales department at info(at)mk-group.com, by phone at +49 2284598-0 or using the contact form below.