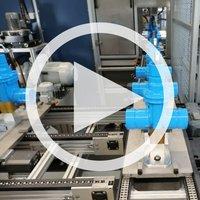

Assembly and buffering section for gate valves

Definition of the task

The customer requires a pallet circulation system for the production of gate valves for water pipes, on which the valves can be assembled and buffered. The system then needs to transport the valves to the customer’s dipping station where they are checked for leaks. Three valves are processed on each pallet, making a total weight of up to 250 kg per pallet. The pallets have to be stopped at the assembly stations. The conveying path needs to be at an ergonomic working height and be secured in accordance with accident prevention regulations (UVV).

Solution from mk

The transfer system was constructed out of chain conveyors and accumulating roller chain conveyors. The profile series used was selected to suit the loads being processed. The conveyors form a circuit on which the alignment of the pallets always remains the same, meaning that there was no need for rotating elements. The pallets are stopped for processing at the assembly stations. Here, the pallets are aligned longitudinally to the conveying direction, allowing workers to easily reach every workpiece. Pressing a button releases the pallet again. On the buffering section, the pallets are transported transversely to the conveying direction. This allows a large number of pallets to be buffered one behind the other in a small space. At the transfer to the customer’s dipping station, the pallets are stopped again and transported further as soon as the dipping station becomes free again. The controller and sensors were installed by the customer themselves.

Benefits for the customer

- Understanding of the customer requirements and appropriate execution

- Reliable partner

- Considerable experience in transfer systems and circulation systems

Products used

> Chain conveyor KTF-P 2010

> Accumulating roller chain conveyor SRF-P 2010