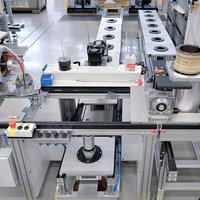

Semi-automated Workstation Interlinking

Problem definition

Design, construction and start-up of a semi-automated workstation interlink system for rotating assemblies for stretching synthetic fibres. The workpiece carriers are provided in three different variants for the rotors, the housings and the finished assemblies. Part of the assembly is carried out on the workpiece carrier; the housing can be swivelled on the workpiece carrier to accomplish the various assembly steps. The project also involved optimising the shop floor press, the joining station and the electrical testing station and interlinking these stations to provide optimal ergonomics and logistics within the given spatial constraints.

mk Solution

Assembly workstation with press: mk shop floor presses were integrated into an mk base frame built from Series 40 profiles, along with a hydraulic assembly, production equipment, a document tray and a testing station. An optimal workstation design was achieved. The workstation’s modular design also allows mk modules/elements to be added to the workstation quickly and easily; Hydraulic shop floor press: The shop floor press is designed for forces up to 70,000 N, with a nominal rating of 2 metric tonnes at 50 bar. Using the mk 2038.85 profile allowed us to fulfil three requirements at once: Modular connection options, made possible by system slots with sturdy M12 connectors. Compact guiding of the pressure plate, made possible by the interior guide rods for ø 10 mm track rollers Clever integration of sturdy steel elements such as the yoke, the base plate and the anvil, which are connected by ø 40 mm drawbars located in mk 2038.75 profiles, into a closed force loop so that they can transfer the large forces of the hydraulic cylinder with maximum stiffness; Joining station:

Custom solution from the mk construction kit for stopping, separating, lifting/lowering and joining at the point of intersection, with minimised installation space and optimised access for the user; Interlinking: Semi-automated interlinking was accomplished with a non-driven accumulating roller chain based on the mk 2010 system, ball roller tables at the points of intersection and supply trolleys. The customer knew from experience that a fully automated solution did not make sense, given the changing products and batch sizes. Semi-automation optimised the ergonomics and capacity at the stations. Manual interlinking was a very cost-effective solution that maintained the necessary flexibility; Testing station: High-voltage electrical test station for dielectric strength testing with an overhanging, balanced protective cover, which is pneumatically fixed using a pedal switch. The testing station is completely insulated and designed for maximum transparency to allow for visual inspection.

Benefits to the customer

- Semi-automated system for maximum capacity while maintaining flexibility

- Cost-effective alternative to full automation

- Individual work steps interlinked by a workpiece carrier system to facilitate assembly

- Ergonomic design facilitates the joining process

- Assembly system is modular, allowing additional assembly steps to be added

Products

> Accumulating roller chain conveyor SRF-P 2010

> Timing belt conveyor

> Workpiece carrier

> Aluminium profile series 50

> Industrial workstation