Problem definition

In the production of longitudinal and cross beams, the production systems, the packaging robots and a station for manual tasks need to be interlinked. Positioning accuracy of +- 0.2 mm is required at the stations. Both longitudinal and cross beams are produced on the line, and the…

Conveying with Specific Functions: Rotating, Lifting, Lowering, Separating, Buffering, Storing, Stopping and Swivelling

Problem definition

Two machining stations in a production process for cast parts need to be interlinked. The upstream and downstream machines have different cycle times. The interlink needs to restore the system’s autonomy. Two different types are produced on the line simultaneously. They are…

Problem definition

A conveyor with a transillumination station is needed for visual inspection in an automated production application. In this station the products are illuminated through the belt and examined with cameras or the naked eye for material defects, incorrect positioning, completeness or…

Problem definition

For an application in the production of non-woven strips, cut sections of non-woven fabric need to be transported from one machining station to the next. The material is very thin and light. The system needs to run at a high speed of 140 m/min. The strips must be transferred from…

Problem definition

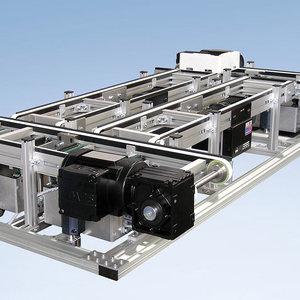

A workpiece carrier circulation system is required for integration into a machine in a logistics process. The circulation system should be as compact as possible and offer suitable connection points so that it can be used as an individual component within the machine.

mk Solution

…

Problem definition

In a food production application, stacked pallets need to be rotated by 90° and then further transported in the same direction so that they can be transferred to a buffer system. The pallets have a length/width ratio of 1 : 2.5, which is unfavourable for rotary motion. One pallet…

Problem definition

In a production system for industrial filters, multiple, separate machining stations need to be interlinked. The interlinks should be as compact as possible. Products of different sizes need to be processed with minimal retooling times. The machine tools should also be able to…

Problem definition

Sheets of various sizes need to be conveyed in a metalworking application. The conveyor technology needs to be easily adjustable for different sheet formats. It also needs to be mobile and flexible. The solution needs to support a total load of 100 kg, and only low speeds are…

Problem definition

Replacement of a simple slide with a system that gently handles blow-molded parts, which in some cases are still plastiline, with automation, and transports them off. The blow-molded parts must be vertically transferred to the discharge gripper of the blow molding system.…

Problem definition

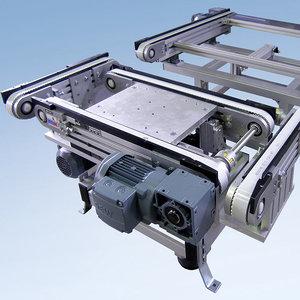

In order to link a manufacturing process, during which a machine that is integrated downstream, functions at a slower speed but operates longer, a transfer system is required using a buffer zone for 40 pallets arranged in 5 levels and capable of transporting a total load of 10…